1

/

of

4

Uploader

Case 1835 Uni-Loader SkidSteer Service Manual Workshop Guide

Case 1835 Uni-Loader SkidSteer Service Manual Workshop Guide

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

•

Service Manual:

884 pages

Specifications:

•

Brand:

New Holland

•

Model:

1835

•

Type:

SkidSteer

•

Manuals:

Service Manual

•

Publication Numbers:

9-68700 (June 1980)

•

Language:

English

•

Format:

PDF

Description

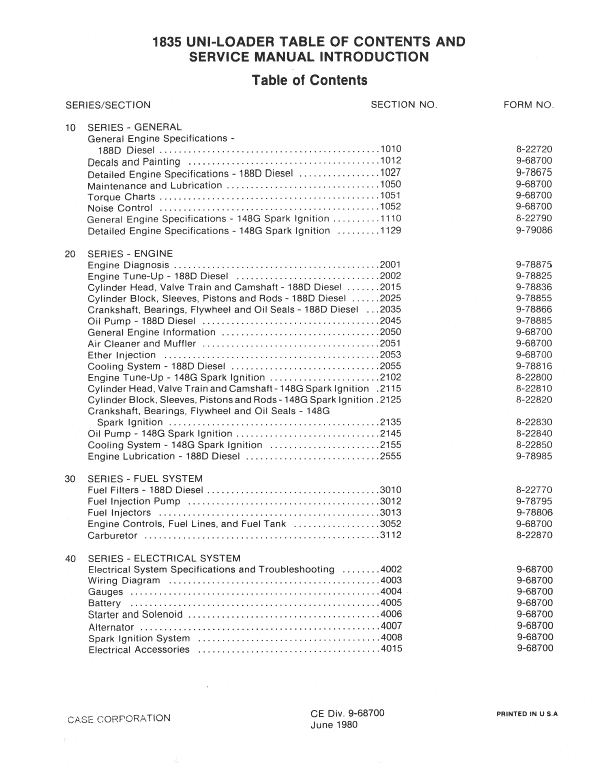

Table of Contents

General

Engines

Fuel System

Electrical

Power Train

Brakes

Hydraulics

Mounted Equipment

Manual Extract: Cooling Oil Mechanism

Lubricating and return 0il flows directly from the closed loop circuit to the oil cooler. This oil is replaced by cooler oil from the charging section of the dual gear pump. This movement of oil is important to the correct cooling of the piston pumps. Since the Case 1835 Uni-Loader the lubricating and return oil comes from passages in the pistons and from leakage, the amount of oil which flows is controlled by the oil pressure within the rotating group. In some conditions, such as travel under light load for extended periods, oil pressure within the rotating group is low in relation to speed of the piston pumps. Under such conditions, the amount of oil being replaced by cooler oil can be too small to keep the position pumps cool. For this reason, the piston pumps on this machine include a cooling oil mechanism.

A cooling oil mechanism is in the back plate of each piston pump. The parts include a spool, a poppet, two springs, and passages drilled in the back plate. A fitting in each back plate is connected to the lines from the charging section of the dual gear pump. When the engine is running, charging pressure holds the spool in a position which opens a passage between the rotating group and the poppet.

When oil pressure within the rotating group is high, the poppet is held against a seat, and the oil from the rotating group cannot flow through the passage. In this condition, there is enough oil from normal leakage to give cooling. If the oil pressure within the rotating group is low, the spring pushes the poppet off the seat. Oil from the rotating group can ilow through the seat, into the pump housing, and back to the oil cooler. This oil is then replaced by cooler oil from the charging section of the dual gear pump.

Share