1

/

of

4

Uploader

Case 580, 590, 695 Super R Backhoe Loader Service Manual Workshop Guide

Case 580, 590, 695 Super R Backhoe Loader Service Manual Workshop Guide

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

•

Service Manual:

1022 pages

Specifications:

•

Brand:

Case

•

Model:

580, 590, 695 Super R

•

Type:

Loader

•

Manuals:

Service Manual

•

Publication Numbers:

87570830A

•

Language:

English

•

Format:

PDF

Description

Table of Contents

Safety Precautions

Maintenance

Technical Specification

Torque Coverters

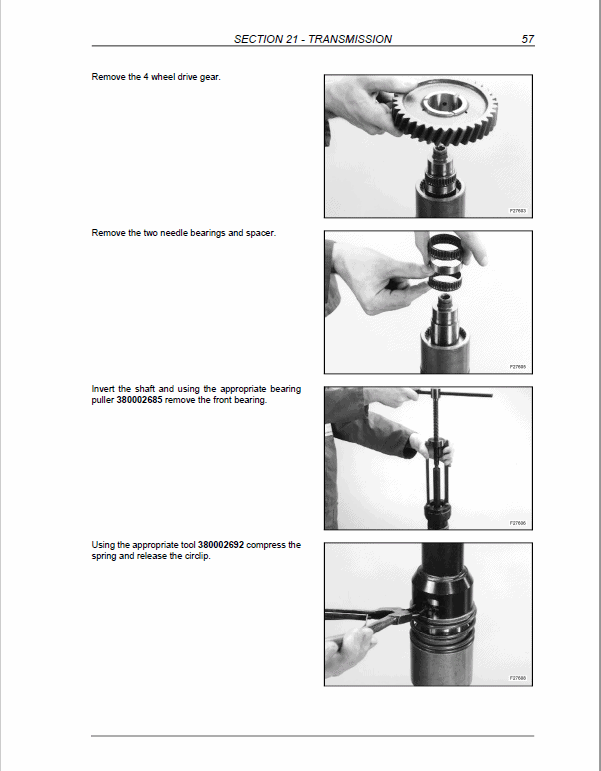

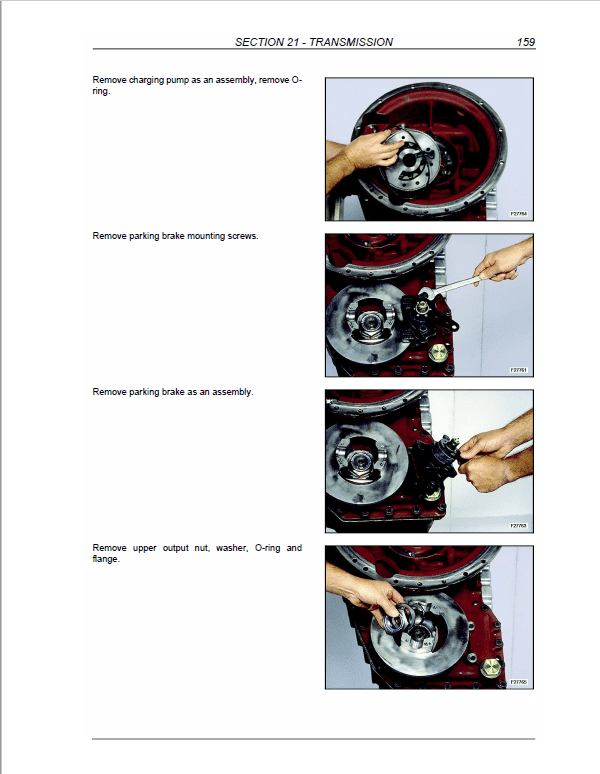

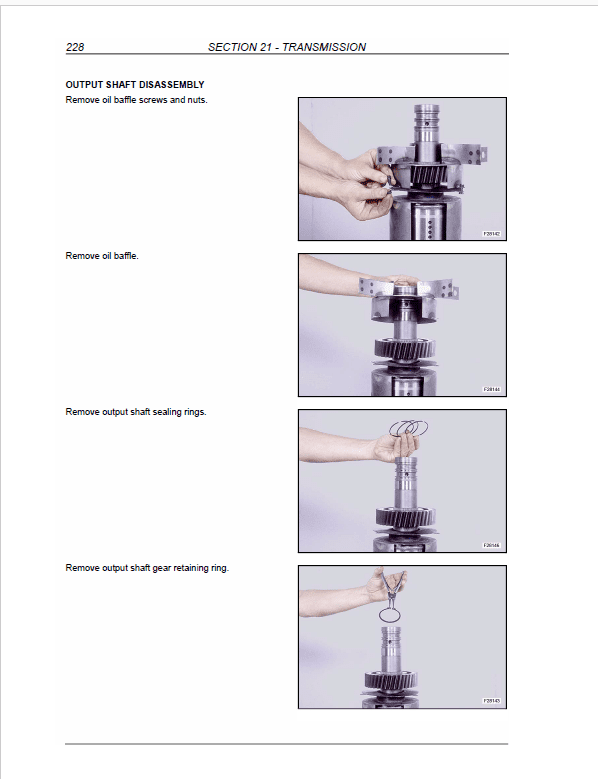

Transmission

Front Axles

Rear Axle

Brake System

Hydraulic System

Chassis

Steering

Cab, Heating and Air conditioning

Electrical System

Loader

Backhoe

Manual Extract: FAULT FINDING

1. Incorrect installation / defective axle

Correct installation or repair or replace the differential in case it does not survive any one of the test phases.

2. Overloading / incorrect weight distribution

Remove excessive weight and redistribute load, following instructions related to the vehicle.

3. Different rotation radius of the tyres

If one tire has a smaller radius, it will cause partial wheel slipping when force is applied. The other tire with bigger radius will have to support all the work. Replace the tire or adjust pressure to have same radius on both tire.

4. Broken half shaft

It is not advisable to operate the vehicle with a broken half shaft. It is acceptable to move the vehicle (engine off unloaded) a few meters away only.

5. Bent half shaft

Replace half shaft.

6. Blocked differential

Abnormal functioning of the differential or breakage/blockage of command device. Verify assembly and all components.

Vehicles with wide steering angle may proceed with kicks, have steering difficulty or cause pneumatic wearing at sharp turns. Reduce the steering angle to minimum and decelerate when the vehicle begins to kick.

7. Incorrect wheel adjustment

Verify group integrity and wheel side bearings.

Adjusting according.

8. Spoiled or worn out axle parts

Check the condition of ring gear, pinion gear, bearings etc.

Replace whenever necessary.

9. Contamination in the axle box or incorrect assembly of parts Look for foreign particles. Check assembly of the various parts of the axle.

10. Incorrect adjustment of bevel gear set: Parts of the transmission worn out. (transmission gears, U joints, etc.)

Replace or adjust as required.

Share