1

/

of

4

Uploader

CAT C3000, C3500, CC4000, C4000 Lift Truck Service Manual

CAT C3000, C3500, CC4000, C4000 Lift Truck Service Manual

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

CAT C3000, C3500, CC4000, C4000 Lift Truck Service Manual: 540 Pages

English

Format: PDF

Description

Caterpillar CAT C3000, C3500, CC4000, C4000 Lift Truck Manual

Lift Truck Forklift Model

: C3000, C3500, CC4000, C4000

English

Format: PDF

CAT C3000, C3500, CC4000, C4000 Lift Truck Service Manual: 540 Pages

Forklift Manual Table of Content:

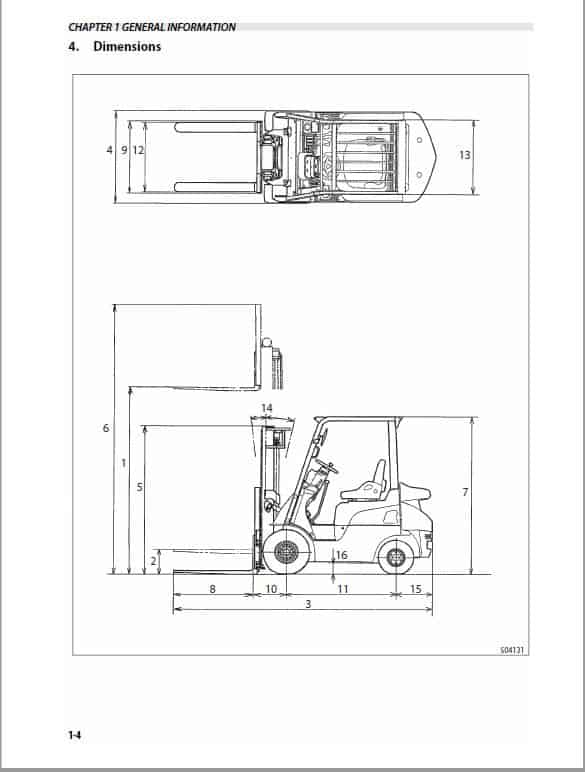

GENERAL INFORMATION

COOLING SYSTEM

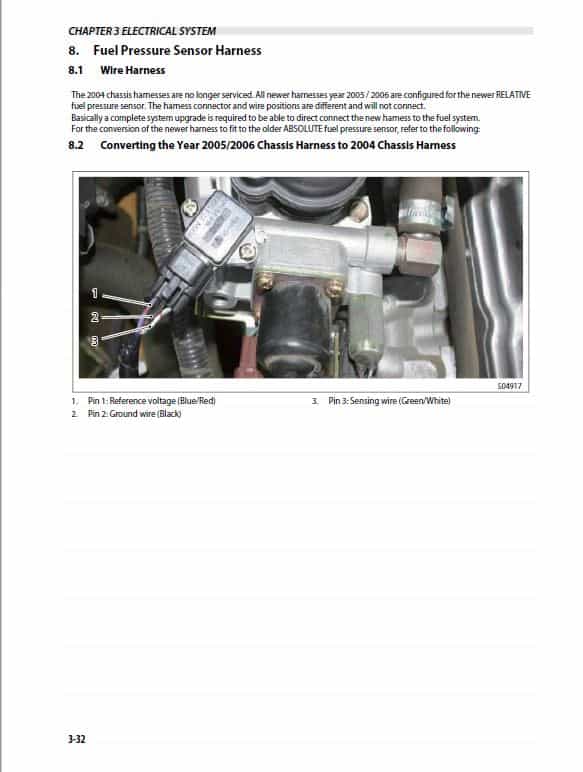

ELECTRIC SYSTEM

CONTROLLERS

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE AND REDUCTION DIFFERENTIAL

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

SERVICE DATA

APPENDIX

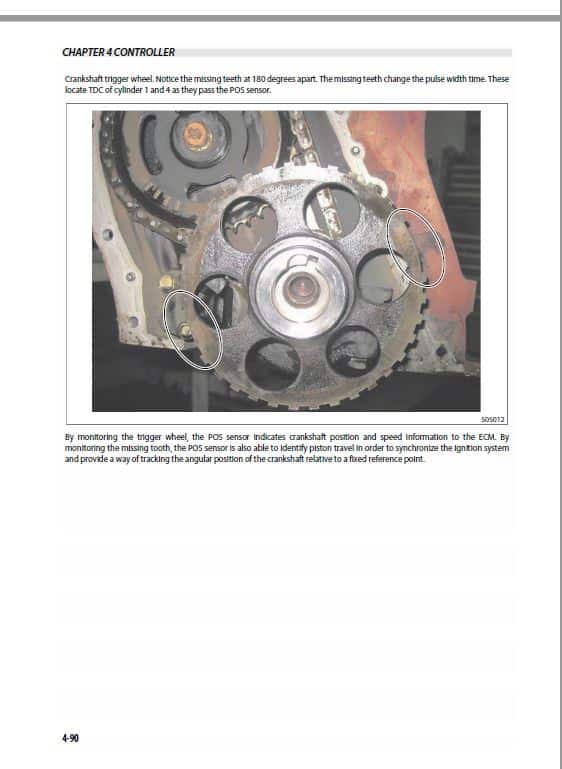

Manual Extract: POS Sensor Warning

The POS signal has not been detected for a length of time. When the engine was being started during phase signal input. An abnormal POS sensor signal wave was detected while the engine was running during phase signal input.

Conditions that can set this code:

If an ignition coil or spark plug fails to fire, the crankshaft will slow down. Low compression in a particular cylinder will cause a slowdown during detonation.

The ECM may set this code if one cylinder slows down as compared to the other cylinders.

Power loss or misfire may be detected. The ECM will try to adjust spark and fuel delivery time within the designed parameter.

Once maximum adjustment is achieved, the ECM will set this code and illuminate the MIL lamp on the display. The crankshaft sensor consists of a POS sensor and a phase sensor that work together (synchronized) as one crankshaft sensor.

The POS sensor detects relative crankshaft position and detects a signal generated by the crankshaft reluctor wheel (located at the end of the crankshaft) as the tips pass in close proximity of the POS hall effect sensor.

The POS sensor also determines engine speed.

The POS sensor sets the injection timing.

POS sensors (crankshaft) are used to signal the engine speed (min-1) and piston position. The position of number one cylinder at top dead center (TDC) is used as a reference for the others in the firing order.

Share