1

/

of

4

Uploader

CAT DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Forklift Service Manual

CAT DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Forklift Service Manual

Regular price

$38.00 USD

Regular price

Sale price

$38.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

CAT Service Manual: 686 Pages

Operation and Maintenance Manual: 204 Pages

1204E Diesel Engine: 880 Pages

Lift Truck Forklift Model: DP100N1, DP120N1, DP135N1, DP150N1, DP160N1

Publication 99799-60100

English

Format: PDF

Description

Caterpillar CAT DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Lift Truck Manual

Lift Truck Forklift Model

: DP100N1, DP120N1, DP135N1, DP150N1, DP160N1

Publication 99799-60100

English

Format: PDF

CAT DP100N1, DP120N1, DP135N1, DP150N1, DP160N1 Forklift Service Manual: 686 Pages

Operation and Maintenance Manual: 204 Pages

1204E Diesel Engine: 880 Pages

Forklift Manual Table of Content:

General Information

Cooling System

Electrical System

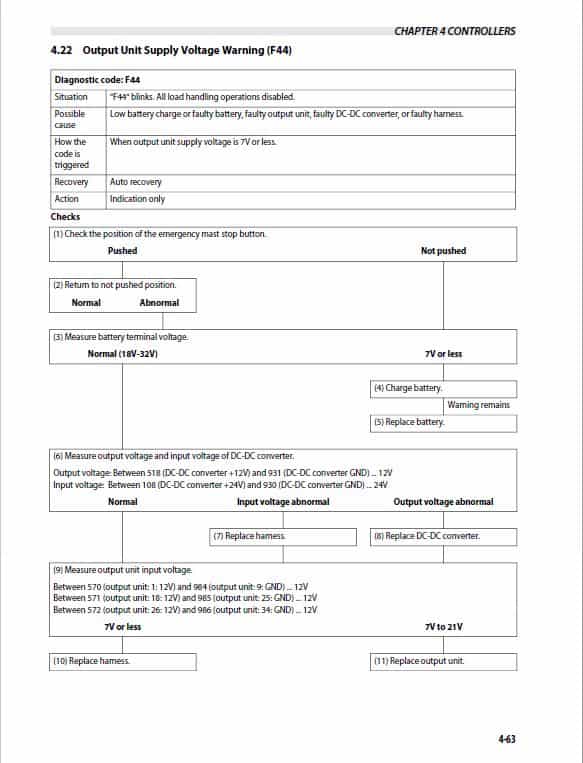

Controllers

Power Train

3-Speed Powershift Transmisions

Front Axle and Reduction Differential

Rear Axle

Brake System

Steering System

Hydraulic System

Masts and Forks

Side Shifter

Fork Positioner

Service Data

How to Read Circuit Diagrams

Circuit Diagram

A knowledge of the system and/or components is important before the removal or disassembly of any component.

Because of the size of some of the lift truck components, the serviceman or mechanic should check the weights noted in this manual.

DO NOT operate these lift trucks unless you have read and understood the instructions in the SERVICE MANUAL. Improper

lift truck operation is dangerous and could result in injury or death.

Use proper lifting procedures when removing any components.

Assembling PTO drive gear

Press in the ball bearing to the PTO drive gear, and tap in the gear to the stator shaft.

Installing oil seal

Replace the oil seals with new ones.

Tap in the oil seal into the torque converter housing with the special tool installer (prepared by the dealer) before assembling.

Subassembly of oil pump

Assemble the pump case, internal gear, pump gear, and pump plate together.

Be sure to apply ATF on the internal gear and pump gear before assembling and install the O-ring.

Installing oil pump subassembly

Be sure to install O-rings on the gasket and oil hole when installing the oil pump subassembly in the transmission case.

Assembling pump drive gear

Install the ball bearing into the pump drive gear. Install two seal rings. Apply ATF and tap the pump drive gear into the transmission case. Align the pump gear splines to assemble.

Installing ball bearing

When tapping the ball bearing, apply the pump drive gear pusher (to be made by the dealer) to prevent the pump drive gear from moving out. Or, have someone press the gear with a copper bar to prevent the gear from moving out.

Share