1

/

of

4

Uploader

CAT GC35K, GC40K, GC40K STR, GC45K SWB, GC45K STR Lift Truck Service Manual

CAT GC35K, GC40K, GC40K STR, GC45K SWB, GC45K STR Lift Truck Service Manual

Regular price

$45.00 USD

Regular price

Sale price

$45.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Lift Truck Forklift Model

: GC35K, GC40K, GC40K STR, GC45K SWB, GC45K STR

English

Format: PDF

Service Manual: 505 Pages

GM 4.3L, G6 Engine LPG Fuel System Supplement: 296 Pages

Operation and Maintenance Manual: 173 Pages

Engine Manual: 183 Pages

Description

Caterpillar CAT GC35K, GC40K, GC40K STR, GC45K SWB, GC45K STR Lift Truck Manual

Lift Truck Forklift Model

: GC35K, GC40K, GC40K STR, GC45K SWB, GC45K STR

English

Format: PDF

Service Manual: 505 Pages

GM 4.3L, G6 Engine LPG Fuel System Supplement: 296 Pages

Operation and Maintenance Manual: 173 Pages

Engine Manual: 183 Pages

Forklift Manual Table of Content:

GENERAL INFORMATION

COOLING SYSTEM

ELECTRIC SYSTEM

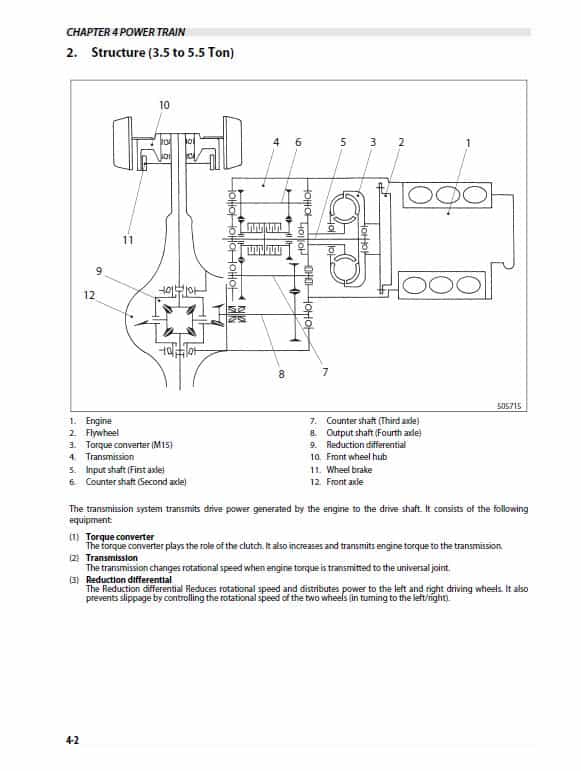

POWER TRAIN

POWERSHIFT TRANSMISSION

FRONT AXLE AND REDUCTION DIFFERENTIAL

REAR AXLE

BRAKE SYSTEM

STEERING SYSTEM

HYDRAULIC SYSTEM

MAST AND FORKS

SERVICE DATA

CIRCUIT DIAGRAM

Manual Extract: Brake System Automatic Adjuster Test

(1) With all wheel brake components installed correctly, the drum-to-shoe clearance should be within the correct range of 0.4 to 0.6 mm (0.016 to 0.024 in.). Push the cable with thumb to pull the adjusting lever.

Observe that the lever turns the adjusting screw by one tooth, and push to observe the adjusting screw returns to the original position.

(2) If the lever fails or is sluggish to turn the adjusting screw in the above test, the possible cause is that the lever is not properly positioned relative to the sprocket wheel.

BE SURE that the lever is positioned so that its actuating tip touches the sprocket wheel at a level about 9 mm (0.35 in.) under the center line of the screw as shown.

(3) Where the automatic adjusting device is suspected of malfunctioning during normal operation, check the following for possible causes:

– Check that springs A and B are correctly installed.

– If any of following parts is in bad condition and requires replacement:

– Fitting cable

– Adjusting lever

– Adjusting screw

Share