1

/

of

4

Uploader

Challenger MT738, MT740, MT743 Tractor Service Manual Workshop Guide

Challenger MT738, MT740, MT743 Tractor Service Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Challenger MT738, MT740, MT743 Tractor Workshop Manual : 1485 Pages

Format: PDF

Book Number: 79037223A

English

Issued January 2018

Description

Challenger MT738, MT740, MT743 Tractor Service Manual

Manual for:

AGCO Challenger

MT700 Series Tractor

Format: PDF

Book Number: 79037223A

English

Issued January 2018

Challenger MT738, MT740, MT743 Tractor Workshop Manual : 1485 Pages

MT700 Series Manual TABLE OF CONTENTS

General. ………………………………………………………………………………..,,..1

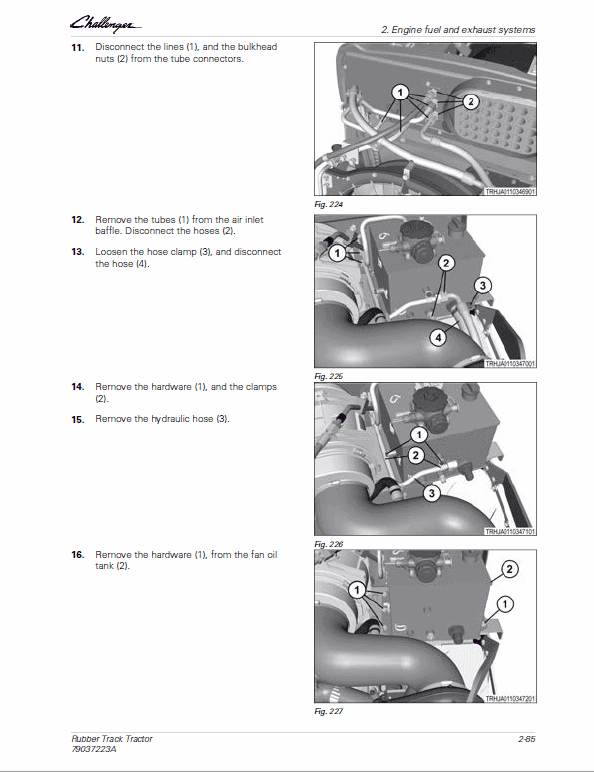

Engine fuel and exhaust systems ………………………………………………. 2

Frame and suspension ………………………………………………………………3

Steering system ………………………………………………………………………. 4

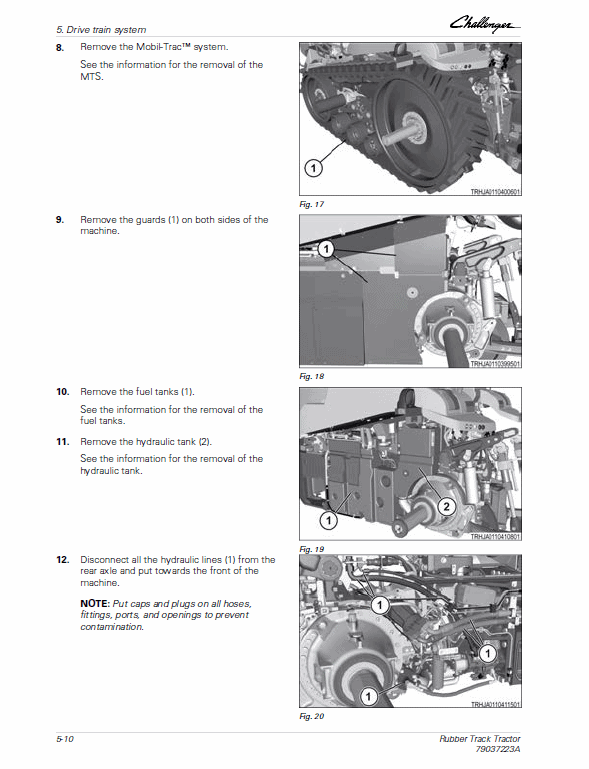

Drive train system …………………………………………………………………… 5

Brake system. …………………………………………………………………………..6

Compressed air system …………………………………………………………….. 7

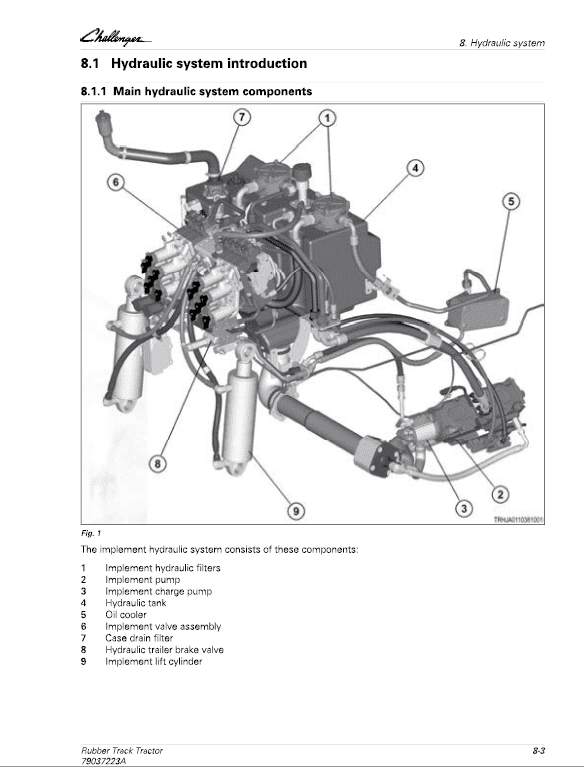

Hydraulic system …………………………………………………………………….. 8

Electrical system ……………………………………………………………………… 9

Cab …………………………………………………………………………………………10

Air conditioning and heating system …………………………………………. 11

Chassis …………………………………………………………………………………… 12

Track belt system ……………………………………………………………………. 13

Implement drive system. …………………………………………………………..14

Implement lift system ……………………………………………………………….15

Attachments. ……………………………………………………………………………16

Special tools ……………………………………………………………………………. 17

MT738, MT740, MT743 Manual Extract- Changing crankshaft rear oil seal

Procedure

1. Lift out the engine.

2. Remove the clutch assembly (and if applicable the turbine clutch).

3. Remove the flywheel.

4. Remove the oil seal.

Do not damage the crankshaft.

5. Clean the seal location and grind off any burrs.

NOTE: If the crankshaft is worn at the sealing location, a 2 mm spacer ring, can be fitted in front of the crankshaft rear oil seal.

6. Fit the seal.

a) Fit the seal dry, not oiled.

b) Put the seal carefully on the shaft.

Make sure that the sealing lip is not damaged.

c) Hit the seal into position with the fitting tool.

Share