1

/

of

4

Uploader

Doosan DX140LC-3 and DX140LC-5 Excavator Service Manual Workshop Guide

Doosan DX140LC-3 and DX140LC-5 Excavator Service Manual Workshop Guide

Regular price

$35.50 USD

Regular price

Sale price

$35.50 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Shop Manual:

900 Pages and 1504 Pages

Specifications:

Brand:

Doosan Excavator

Model:

DX140LC-3 and DX140LC-5

Serial Number:

1001 and Up

Type:

Excavator

Manuals:

Shop Manual

Publication Number:

950106-00388E (April 2012) and 950106-01141E (Feb 2015)

Language:

English

Format:

PDF

Description

Table of Contents:-

Safety

Track Excavator Maintenance Safety …………………………………………… SP002322

Specifications

Specifications for DX140LC-3……………………………………………………… SP002509

General Maintenance

General Maintenance Instructions……………………………………………….. SP002454

Standard Torques……………………………………………………………………… SP002404

Upper Structure

Cabin ………………………………………………………………………………………. SP002324

Counterweight…………………………………………………………………………… SP002510

Fuel Tank…………………………………………………………………………………. SP002511

Fuel Transfer Pump (Option) ………………………………………………………. SP002546

Swing Bearing…………………………………………………………………………… SP002329

Swing Reduction Gear……………………………………………………………….. SP002526

Lower Structure and Chassis

Track Assembly ………………………………………………………………………… SP002512

Engine and Drivetrain

Engine Coolant Heater (Option) ………………………………………………….. SP002328

Drive Coupling (Main Pump)……………………………………………………….. SP002515

Hydraulics

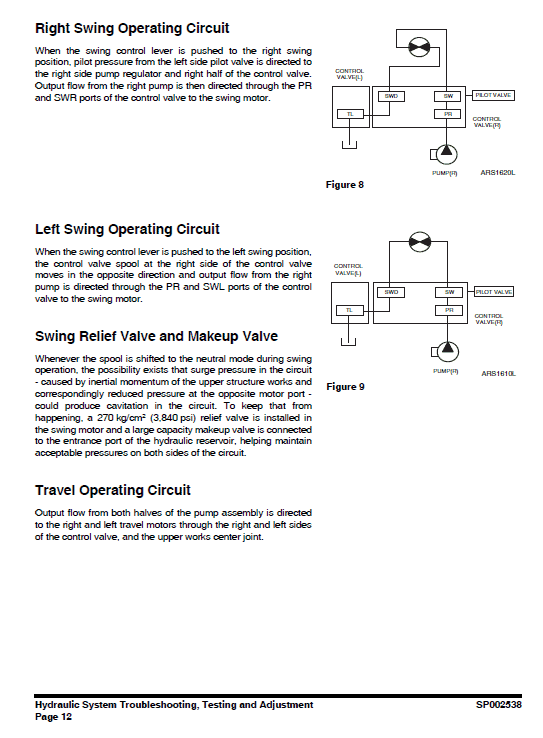

Hydraulic System Troubleshooting, Testing and Adjustment …………… SP002538

Accumulator……………………………………………………………………………… SP002455

Center Joint (Swivel)………………………………………………………………….. SP002456

Cylinders………………………………………………………………………………….. SP002539

Swing Motor……………………………………………………………………………… SP002527

Travel Device……………………………………………………………………………. SP002516

Main Pump……………………………………………………………………………….. SP002517

Gear Pump ………………………………………………………………………………. SP002500

Main Control Valve ……………………………………………………………………. SP002528

Remote Control Valve (Work Lever / Joystick) ………………………………. SP002395

Travel Control Valve (with Damper)……………………………………………… SP002381

Solenoid Valve Assembly …………………………………………………………… SP002406

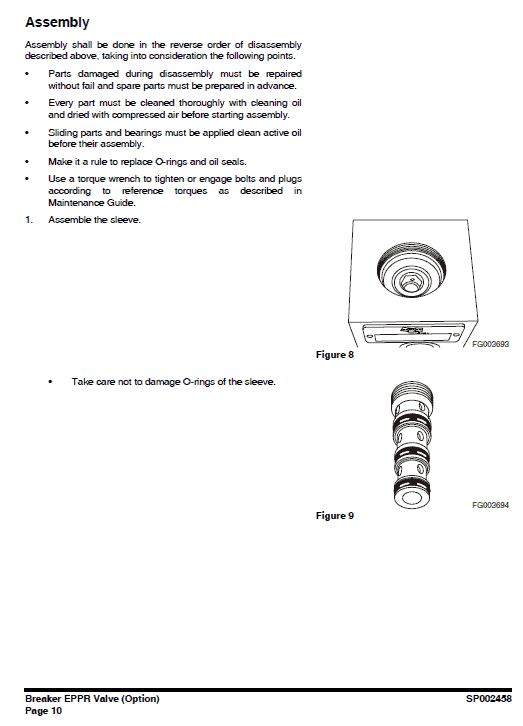

Breaker EPPR Valve (Option) …………………………………………………….. SP002458

Dozer Valve ……………………………………………………………………………… SP002529

Hydraulic Schematic (DX140LC-3& DX140LC-5)…………………………. SP002518

Electrical System

Electrical System ………………………………………………………………………. SP002337

Electrical Schematic ………………………………………………………………….. SP002508

Attachments

Boom and Arm………………………………………………………………………….. SP002513

Bucket……………………………………………………………………………………… SP002506

Doosan DX140LC-3 and DX140LC-5 Manual Instruction Extract:

Fuel Injectors

Overview

NOTE: If a replacement electronic unit injector is installed, the correct injector code must be programmed into the electronic control module. The code that is required is located at position (X). Record code (X) before the electronic unit injector is installed.

The fuel injectors contain no serviceable parts apart from the O-ring seal and the combustion washer. The clamp and setscrew are serviced separately. The pressurized fuel from the fuel manifold is injected into the combustion chamber by the electronic unit injector. The desired injection timing, injection quantity and injection pattern are controlled by the ECM depending on engine operating conditions.

The injection process is controlled using a two-way valve. The supply of electrical current to the solenoid controls the two-way valve. When the two-way valveis not energized the out orifice is closed and there is no fuel leak. In this condition the pressure in the control chamber and the pressure at the nozzle needle are the same. In this condition the spring pressure on the command piston keeps the needle closed.

When an injection of fuel is required, the electrical current from the ECM charges the solenoid, which in turn energizes the two-way valve and lifts the valve.

When the valve lifts the valve uncovers the out orifice. The fuel starts to flow and reduces the pressure in the control chamber. When the pressure difference at the nozzle needle exceeds the combined pressure of the control chamber pressure and the spring pressure, the nozzle lifts to start the injection process. The fuel coming out of the nozzle is atomized and injected as a very fine spray.

When the injection needs to be stopped the electrical current to the solenoid is cut off and the pressure difference in the control chamber starts increasing. The increased pressure difference stops the injection process when the combined pressure exceeds the nozzle pressure.

The electronic unit injectors can be instructed to inject fuel multiple times during the combustion process.

A close pilot injection occurs before the main injection.

The close pilot injection helps to reduce NOx and noise. The main injection period helps to increase the torque of the engine. The after injection period helps to reduce the amount of smoke that is produced.

How to Use The Doosan DX140LC-3 and DX140LC-5 Excavator Guide Manual:

This manual provides information for servicing the DX140LC-3 and DX140LC-5 Doosan Excavator. All service procedures are broken down into detailed steps, listed in their recommended sequence. The manual uses both photographs and drawings to help locate and itemize components. The table of Contents on the preceding pages is your best tool for finding the service procedure you need. Be certain to observe all Safety information included in these pages.

A schematic of each of the major engine systems is provided at the beginning of the section of the manual devoted to troubleshooting and repairing that particular system.

Basic safety precautions are list in the Safety section of the Doosan DX140LC-3 and DX140LC-5 Excavator Service Manual. Additional safety precautions are list in the Safety section of the owner/operation/maintenance publication. Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

Share