1

/

of

4

Uploader

Doosan DX210W Excavator Service Manual Workshop Guide

Doosan DX210W Excavator Service Manual Workshop Guide

Regular price

$35.00 USD

Regular price

Sale price

$35.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Service Manual:

1186 Pages

Specifications:

Brand:

Doosan Excavator

Model:

DX210W

Serial Number:

5001 and Up

Type:

Excavator

Manuals:

Service Manual

Publication Number:

K1017314AE

Language:

English

Format:

PDF

Description

Table of Contents:-

Safety

Wheel Excavator Safety …………………………………………………………….. SP000956

Specifications

Specification for DX210W…………………………………………………………… SP000957

General Maintenance

General Maintenance Procedures……………………………………………….. SP000016

Standard Torques……………………………………………………………………… SP000813

Upper Structure

Cabin ………………………………………………………………………………………. SP001231

Counterweight…………………………………………………………………………… SP000959

Fuel Tank…………………………………………………………………………………. SP000961

Fuel Transfer Pump…………………………………………………………………… SP000021

Swing Bearing…………………………………………………………………………… SP001232

Swing Reduction Gear……………………………………………………………….. SP001233

Lower Structure and Chassis

Ram Lock Valve………………………………………………………………………… SP000923

Selector Valve…………………………………………………………………………… SP000926

Double Pilot Check Valve …………………………………………………………… SP000927

Solenoid Valve………………………………………………………………………….. SP000928

Front Axle ………………………………………………………………………………… SP000929

Rear Axle…………………………………………………………………………………. SP000930

Engine and Drive Train

Transmission ……………………………………………………………………………. SP000962

Drive Coupling (Main Pump)……………………………………………………….. SP000963

Hydraulics

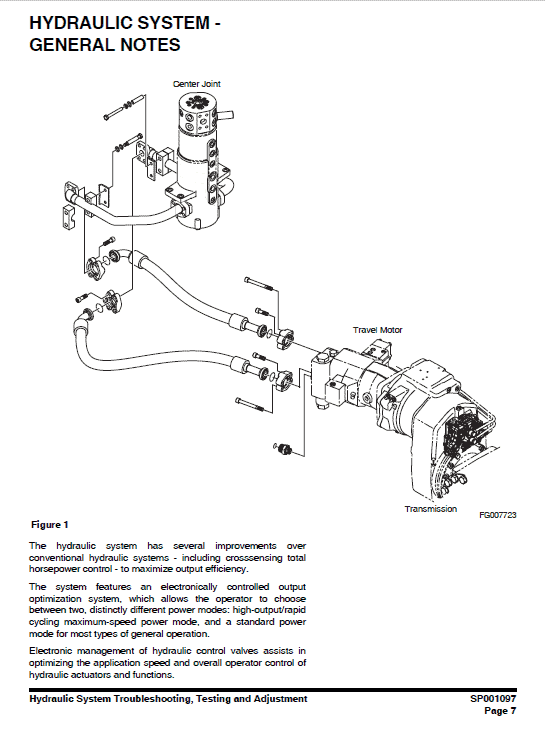

Hydraulic System Troubleshooting, Testing and Adjustment …………… SP001097

Accumulator……………………………………………………………………………… SP000984

Center Joint (Swivel)………………………………………………………………….. SP000919

Cylinders………………………………………………………………………………….. SP001098

Main Control Valve ……………………………………………………………………. SP000966

Swing Motor……………………………………………………………………………… SP000985

Travel Motor……………………………………………………………………………… SP001110

Counterbalance Valve ……………………………………………………………….. SP000991

Main Pump & PTO…………………………………………………………………….. SP000988

Gear Pump ………………………………………………………………………………. SP000989

Service Brake Supply Valve ……………………………………………………….. SP000990

Dozer Control Valve…………………………………………………………………… SP000992

Steering Valve ………………………………………………………………………….. SP000993

Accelerator Pedal Valve (Hydraulic) …………………………………………….. SP000964

One Spool Valve……………………………………………………………………….. SP000996

Remote Control Valve (Work Lever / Joystick) ………………………………. SP000069

Breaker EPPR Valve (Opt) …………………………………………………………. SP000192

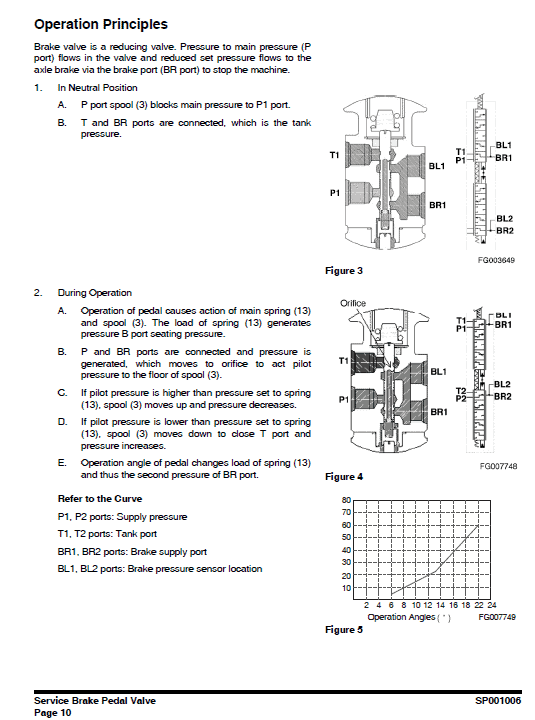

Service Brake Pedal Valve …………………………………………………………. SP001006

Solenoid Valve Assembly …………………………………………………………… SP000997

Hydraulic Schematic………………………………………………………………….. SP001107

Electrical System

Electrical System ………………………………………………………………………. SP001108

Electrical Schematic ………………………………………………………………….. SP001256

Attachments

Boom and Arm………………………………………………………………………….. SP001255

Bucket……………………………………………………………………………………… SP001001

Doosan DX210W Manual Instruction Extract:

Inspection

The center joint should be checked for evidence of external oil leakage every 2,000 operating hours. Leaking or defective Orings are an indication that dirt and other contaminants could be getting inside the assembly, which will promote accelerated, abnormal wear and may cause early failure of the assembly.

If internal seals or other sliding surface components are worn and there is internal fluid leakage, complete overhaul and repair or replacement of the center joint may be required.

Testing

To check pressure through the center joint, make up a test kit from the following equipment list:

• 700 bar (10,000 psi) pressure gauge.

• Adapters, connectors, piping and flange block-off plates conforming to those used in high-pressure piping connections of the excavator.

• A high-pressure relief valve with a setting pressure 1.5 times maximum system pressure.

• A stop valve.

• A manually operated, in-line changeover valve.

Install the changeover valve upstream from one of the stem high-pressure ports. Connect the pressure gauge downstream from one of the body ports. Install the stop valve between the changeover valve and the stem of the center joint. Other components should be installed according to the layout in the block diagram. The test kit is used to pressurize the center swivel above normal working pressure and lock in the higher pressure (as the stop valve is closed manually) for a leak down test.

NOTE: The same type of kit can also be made up for the drain port (return line) side of the center joint. Use appropriate piping, connectors, test gauges, etc., and follow the same block diagram general layout (Figure 2).

How to Use The Doosan DX210W Excavator Guide Manual:

This manual provides information for servicing the DX210W Doosan Excavator. All service procedures are broken down into detailed steps, listed in their recommended sequence. The manual uses both photographs and drawings to help locate and itemize components. The table of Contents on the preceding pages is your best tool for finding the service procedure you need. Be certain to observe all Safety information included in these pages.

A schematic of each of the major engine systems is provided at the beginning of the section of the manual devoted to troubleshooting and repairing that particular system.

Basic safety precautions are list in the Safety section of the Doosan DX210W Excavator Service Manual. Additional safety precautions are list in the Safety section of the owner/operation/maintenance publication. Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

Share