1

/

of

4

Uploader

Doosan DX340LCA Excavator Service Manual Workshop Guide

Doosan DX340LCA Excavator Service Manual Workshop Guide

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Shop Manual:

818 Pages

Specifications:

Brand:

Doosan

Model:

DX340LCA

Serial Number:

5000 and Up

Type:

Excavator

Manuals:

Shop Manual

Publication Numbers:

950106-00268E

Language:

English

Format:

PDF

Description

Table of Contents

Safety

Track Excavator Safety………………………………………………………………. SP002025

Specifications

Specification for DX340LCA ……………………………………………………….. SP002320

General Maintenance

General Maintenance Procedures……………………………………………….. SP000016

Standard Torques……………………………………………………………………… SP000813

Upper Structure

Cabin ………………………………………………………………………………………. SP001737

Counterweight…………………………………………………………………………… SP001738

Fuel Tank…………………………………………………………………………………. SP002321

Fuel Transfer Pump (Opt)…………………………………………………………… SP000021

Swing Bearing…………………………………………………………………………… SP001856

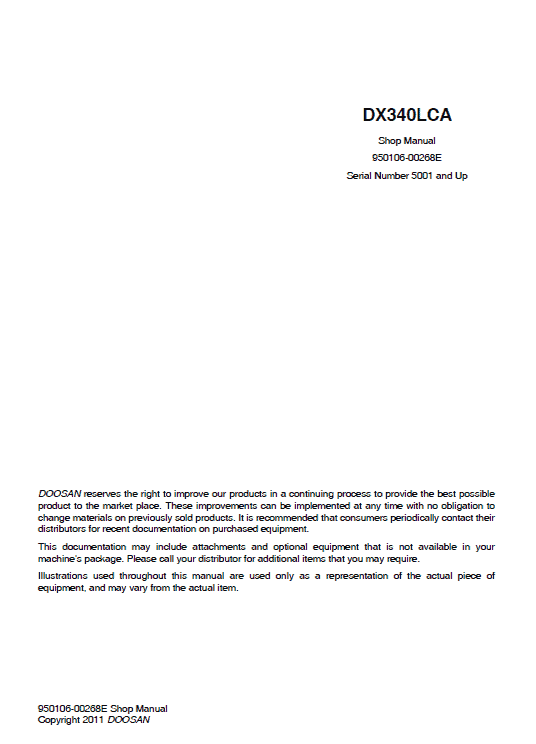

Swing Reduction Gear……………………………………………………………….. SP001740

Lower Structure and Chassis

Track Assembly ………………………………………………………………………… SP001741

Engine and Drive Train

Drive Coupling (Main Pump)……………………………………………………….. SP000026

Hydraulics

Hydraulic System Troubleshooting, Testing and Adjustment …………… SP002451

Accumulator……………………………………………………………………………… SP000028

Center Joint (Swivel)………………………………………………………………….. SP000181

Cylinders………………………………………………………………………………….. SP000030

Swing Motor……………………………………………………………………………… SP000261

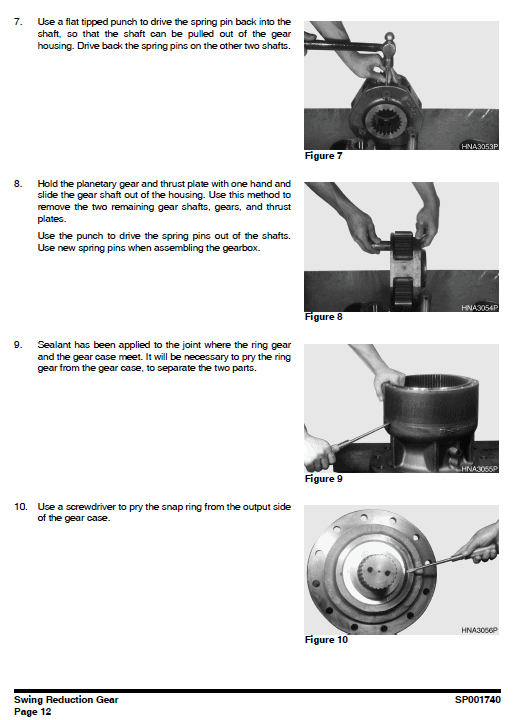

Travel Motor……………………………………………………………………………… SP000253

Main Pump……………………………………………………………………………….. SP000186

Gear Pump ………………………………………………………………………………. SP000260

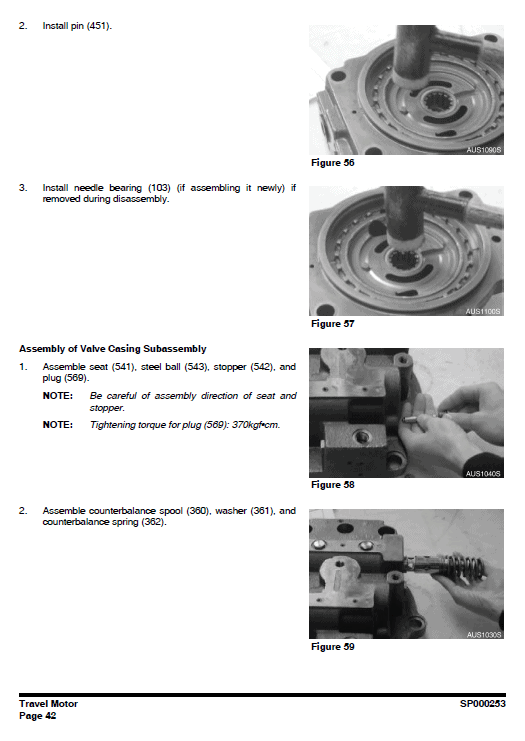

Main Control Valve ……………………………………………………………………. SP000034

Remote Control Valve (Work Lever / Joystick) ………………………………. SP000069

Travel Control Valve (With Damper)…………………………………………….. SP001743

Solenoid Valve Assembly …………………………………………………………… SP001622

Breaker EPPR Valve (Opt) …………………………………………………………. SP000192

Hydraulic Schematic DX300LC/DX300LCA/DX340LCA …………………. SP001752

Electrical System

Electrical System………………………………………………………………………. SP002453

Electrical Schematic DX300LCA / DX340LCA ………………………………. SP002031

Attachments

Boom and Arm………………………………………………………………………….. SP001851

Bucket……………………………………………………………………………………… SP001852

How to Use The Guide Manual:

This manual provides information for servicing the DX340LCA Doosan Excavator. All service procedures are broken down into detailed steps, listed in their recommended sequence. The manual uses both photographs and drawings to help locate and itemize components. The table of Contents on the preceding pages is your best tool for finding the service procedure you need. Be certain to observe all Safety information included in these pages.

A schematic of each of the major engine systems is provided at the beginning of the section of the manual devoted to troubleshooting and repairing that particular system.

Basic safety precautions are list in the Safety section of the Doosan DX340LCA Excavator Service Manual. Additional safety precautions are list in the Safety section of the owner/operation/maintenance publication. Specific safety warnings for all these publications are provided in the description of operations where hazards exist. WARNING labels have also been put on the product to provide instructions and to identify specific hazards.

Instructions Manual Extract:

Symptoms

Possible Causes

Remedies

1. No rotation and

a. Pressure at swing motor inlet increase.

b. Pressure at swing motor inlet shows no increase, and the swing motor is making irregular noises.

c.Pressure at swing motor inlet shows no increase, but without irregular noises from the swing motor.

Swing brake not releasing

Internal damage to gearbox drive train

Overload

Swing motor drive shaft damage

Internal damage to gearbox drive train

Hydraulic pump or valve broken

Check brake engagement and disengagement, check release pressure

Replace broken gears, drive train assemblies

Reduce load weight

Replace swing motor

Repair/replace broken or faulty assemblies

Troubleshoot hydraulic System

2. Oil leakage

a. From drive shaft

b. From bolted connections or other assembled surfaces

Oil seal damaged

Assembly compound (joint sealer) old and not sealing, bolt not tight or flange warped

Replace oil seal

Disassemble and check mating surfaces. Reapply Loctite, torque bolts to specifications

3. Excess heat

Gearbox casing becomes excessively hot, with or without irregular noise(s) during operation

Low oil level

Bearings or gear worn but not completely inoperative

Replace oil, refill to specified level

Repair or replace gearbox

Share