1

/

of

4

Uploader

Hino 145, 165, 185, 238, 268, 308, 338 Series Year 2007 Repair Manual Workshop Guide

Hino 145, 165, 185, 238, 268, 308, 338 Series Year 2007 Repair Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

This is the Repair and Service Manual for

Hino Truck

2007

Series: 145 (NA6J), 165 (NB6J), 185 (NC6J), 238 (ND8J), 268 (NE8J, NJ8J), 308 (NF8J) and 338 (NV8J) with J05D-TA, J08E-TA and J08E-TB engine

Format: PDF

Language: English

Hino 2007 Truck 145, 165, 185, 238, 258, 268, 338 Series Manual – 1162 Pages

Hino 2007 Owners Manual – 274 Pages

Hino J05D-TA Engine Manual – 324 Pages

Hino J08E-TA and J08E-TB Engine Manual – 351 Pages

Description

Hino 145, 165, 185, 238, 268, 338 Series Year 2007 Repair Manual

This is the Repair and Service Manual for

Hino Truck

2007

Series: 145 (NA6J), 165 (NB6J), 185 (NC6J), 238 (ND8J), 268 (NE8J, NJ8J), 308 (NF8J) and 338 (NV8J) with J05D-TA, J08E-TA and J08E-TB engine

Format: PDF

Language: English

Hino 2007 Truck 145, 165, 185, 238, 258, 268, 338 Series Manual – 1162 Pages

Hino 2007 Owners Manual – 274 Pages

Hino J05D-TA Engine Manual – 324 Pages

Hino J08E-TA and J08E-TB Engine Manual – 351 Pages

This workshop manual has been prepared to provide information covering repairs on 145, 165, 185, 238, 258, 268, 338 series Hino 2007 trucks.

To use Hino 2007 trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

Table of Content For Hino 2007 Truck Manual:

General Introduction

Clutch Equipment

Clutch Main Unit

Clutch Control

Transmission Equipment

Transmission Main Unit

Transfer Main Unit

Automatic Transmission

P.t.o. (Power Take-off)

Transmission / Transfer Control

Propeller Shaft

Differential Equipment

Differential Carrier

Index: Chassis Group 1/4

Propeller Shaft Equipment

Brake Equipment

Service Brake

Abs & Asr

Es Start (Easy & Smooth Start) System

Exhaust Brake

Retarder Brake

Parking Brake

Steering Equipment

Steering Unit

Power Steering

Axle Equipment

Front Axle

Rear Axle

Wheel & Tire

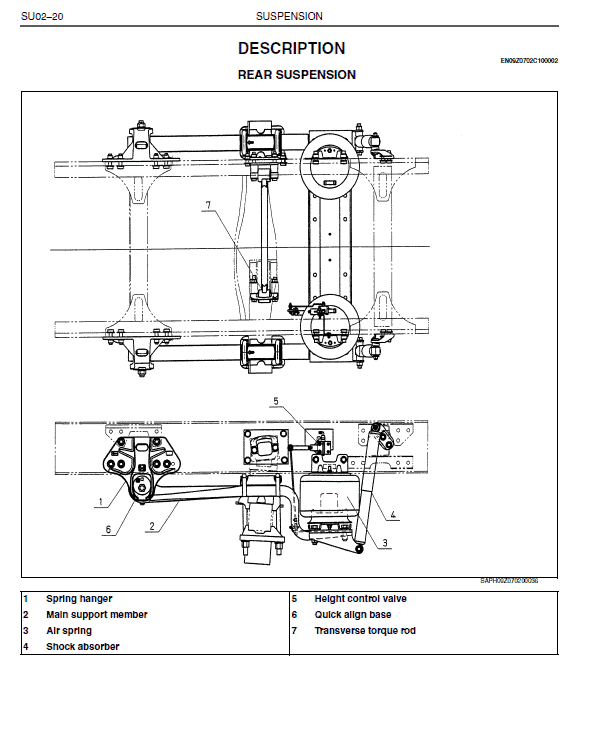

Suspension Equipment

Suspension

Chassis Equipment

Chassis Frame

Coupler (5th Wheel)

Pintle Hook

Hino Truck 2007 Manual Instruction Extract:

INSPECTION AND REPAIR

To prevent serious eye injury, always wear safe eye protection when you perform vehicle maintenance or service.

Solvent cleaners can be flammable, poisonous and cause burns.

Examples of solvent cleaners are carbon tetrachloride, emulsion-type cleaners and petroleum-based cleaners. To avoid serious personal injury when you use solvent cleaners, you must carefully follow the manufacturer's product instructions and these procedures: Wear safe eye protection.

• Wear clothing that protects your skin.

• Work in a well-ventilated area.

• Do not use gasoline, or solvents that contain gasoline. Gasoline can explode.

• You must use hot solution tanks or alkaline solutions correctly.

Follow the manufacturer's instructions carefully.

1. CLEAN GROUND AND POLISHED PARTS

(1) Use a cleaning solvent to clean ground or polished parts or surfaces.

Kerosene or diesel fuel oil can be used for this purpose. DO NOT USE GASOLINE.

(2) Use a tool with a flat blade if required, to remove sealant material from parts. Be careful not to damage the polished or smooth surfaces.

! CAUTION

Do not use hot solution tanks or water and alkaline solutions to clean ground or polished parts. Damage to parts will result.

(3) Do not clean ground or polished parts with water or steam. Do not immerse ground or polished parts in a hot solution tank or use strong alkaline solutions for cleaning, or the smooth sealing surface may be damaged.

2. CLEAN ROUGH PARTS

(1) Clean rough parts with the same method as cleaning ground and polished parts.

(2) Rough parts can be cleaned in hot solution tanks with a weak or diluted alkaline solution.

(3) Parts must remain in hot solution tanks until heated and completely cleaned.

(4) Parts must be washed with water until all traces of the alkaline solution are removed.

3. CLEAN AXLE ASSEMBLIES

(1) A complete axle assembly can be steam cleaned on the outside to remove dirt.

(2) Before the axle is steam cleaned, close or place a cover over all openings in the axle assembly. Examples of openings are breathers or vents in air chambers.

4. DRY PARTS AFTER CLEANING

(1) Parts must be dried immediately after cleaning and washing.

(2) Dry the parts using soft, clean paper or cloth rags.

! CAUTION

Damage to bearings can result when they are rotated and dried with compressed air.

(3) Except for bearings, parts can be dried with compressed air.

5. PREVENT CORROSION ON CLEANED PARTS

(1) Apply axle lubricant to cleaned and dried parts that are not damaged and are to be assembled.

(2) To store parts, apply a special material that prevents corrosion to all surfaces. Wrap cleaned parts in a special paper that will protect the parts from moisture and prevent corrosion.

6. INSPECT PARTS

It is very important to inspect all parts carefully and completely before the axle or carrier is assembled. Check all parts for wear and replace damaged parts.

(1) Inspect the cup, cone, rollers and cage of all tapered roller bearings in the assembly. If any of the following conditions exist, replace the bearing.

• The center of the large-diameter end of the rollers is worn level with or below the outer surface.

• The radius at the large-diameter end of the rollers is worn to a sharp edge.

• There is a visible roller groove in the cup or cone inner race surfaces.

The groove can be seen at the small- or large-diameter end of both parts.

• There are deep cracks or breaks in the cup, cone inner race or roller surfaces.

Share