1

/

of

4

Uploader

Hino 145, 165, 185, 238, 268, 338 Series Year 2005 Repair Manual Workshop Guide

Hino 145, 165, 185, 238, 268, 338 Series Year 2005 Repair Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

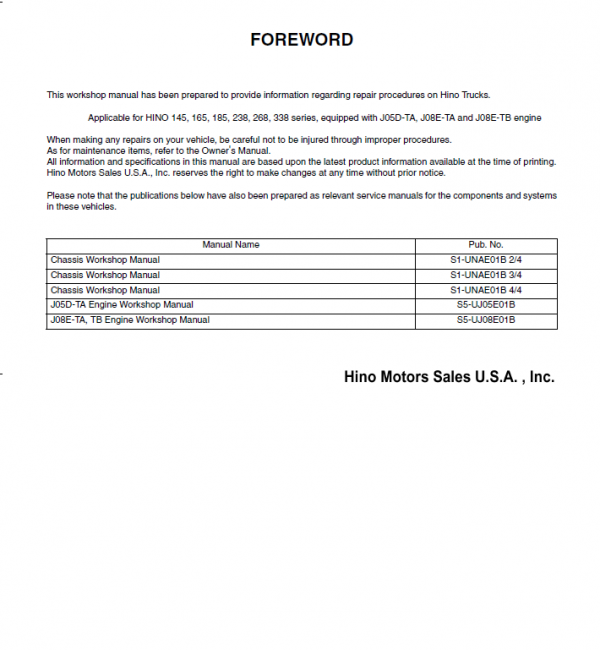

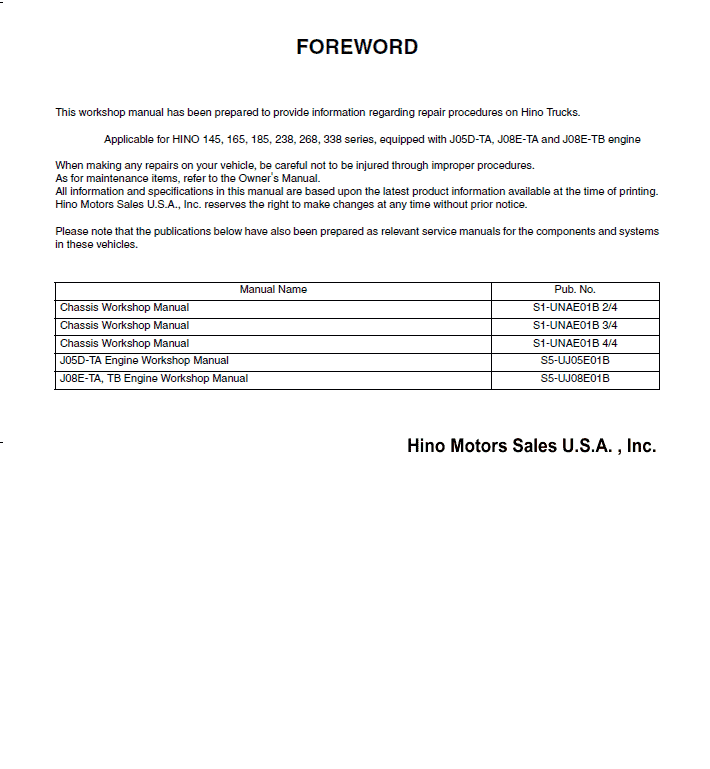

This is the Repair and Service Manual for

Hino Truck

2005

Series: 145 (NA6J), 165 (NB6J), 185 (NC6J), 238 (ND8J), 268 (NE8J, NJ8J) and 338 (NV8J)

Equipped with J05D-TA, J08E-TA and J08E-TB engine

Format: PDF

Language: English

Hino 2005 Truck 145, 165, 185, 238, 268 and 338 Series Manual – 1376 Pages

Hino 2005 Truck Owners Manual – 266 Pages

Hino J08E-TA and J08E-TB Engine Manual – 351 Pages

Hino J05D-TA Engine Manual – 324 Pages

Description

Hino 145, 165, 185, 238, 268, 338 Series Year 2005 Repair Manual

This is the Repair and Service Manual for

Hino Truck

2005

Series: 145 (NA6J), 165 (NB6J), 185 (NC6J), 238 (ND8J), 268 (NE8J, NJ8J) and 338 (NV8J)

Equipped with J05D-TA, J08E-TA and J08E-TB engine

Format: PDF

Language: English

Hino 2005 Truck 145, 165, 185, 238, 268 and 338 Series Manual – 1376 Pages

Hino 2005 Truck Owners Manual – 266 Pages

Hino J08E-TA and J08E-TB Engine Manual – 351 Pages

Hino J05D-TA Engine Manual – 324 Pages

This workshop manual has been prepared to provide information covering repairs on 145, 165, 185, 238, 268 and 338 series Hino 2005 trucks.

To use Hino 2005 trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

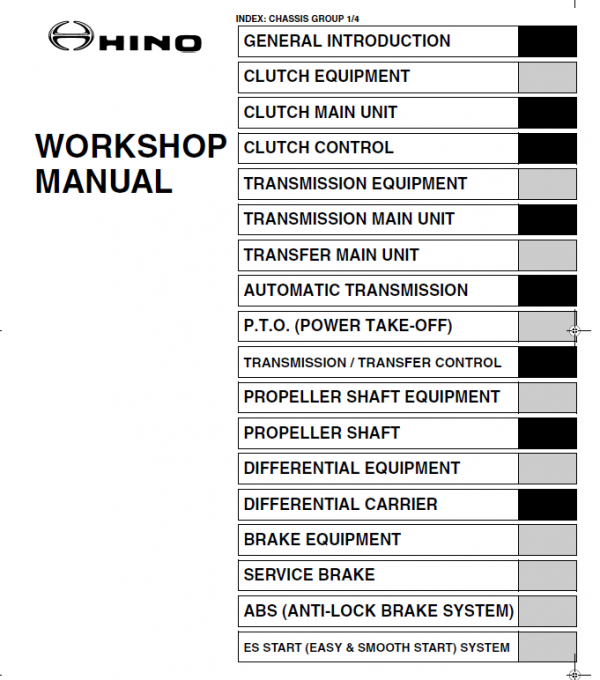

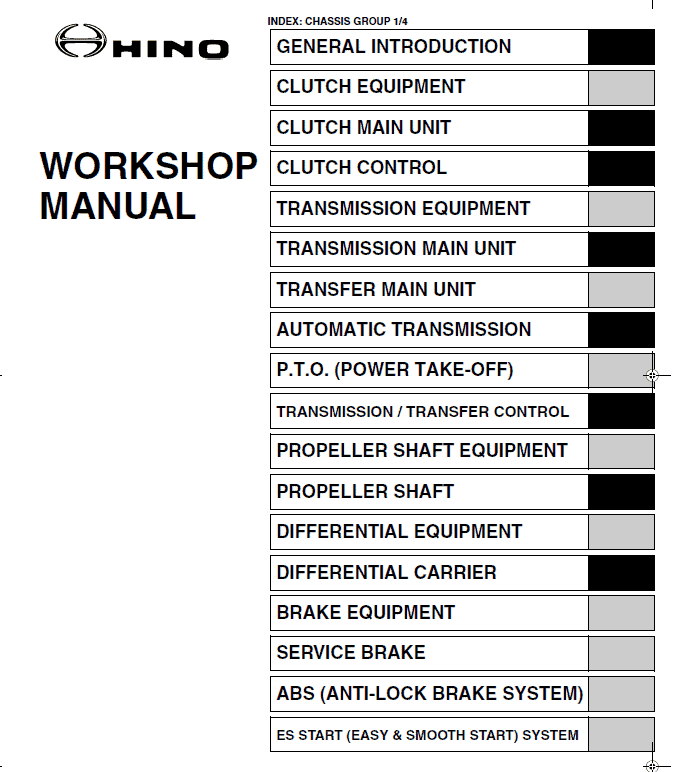

Table of Content For Hino 2005 Truck Manual:

General Introduction

Clutch Equipment

Clutch Main Unit

Clutch Control

Transmission Equipment

Transmission Main Unit

Transfer Main Unit

Automatic Transmission

P.t.o. (Power Take-off)

Transmission / Transfer Control

Propeller Shaft

Differential Equipment

Differential Carrier

Index: Chassis Group 1/4

Propeller Shaft Equipment

Workshop

Manual

Brake Equipment

Service Brake

Abs (Anti-lock Brake System)

Es Start (Easy & Smooth Start) System

Exhaust Brake

Retarder Brake

Parking Brake

Steering Equipment

Steering Unit

Power Steering

Index: Chassis Group 2/4

Axle Equipment

Front Axle

Rear Axle

Wheel & Tire

Suspension Equipment

Suspension

Chassis Equipment

Chassis Frame

Coupler (5th Wheel)

Pintle Hook

Cab Equipment

Cab

Electrical Equipment

Electric Wire

Hino Truck 2005 Manual Instruction Extract:

How to Assemble the the FSO-6406/8406 Shift Bar Housing Special Instructions

Interlock balls, detent balls, and springs can be used interchangeably.

Lubricate yoke pads and inserts with oil before assembly.

Lubricate yoke bar grooves with grease before assembly.

Keep yoke bars in neutral while assembling.

The shift yoke retainer holes are not tapped on new shift bar housings. The capscrews that are used are thread forming and can be reused if the shift bar housing is replaced.

It may be necessary to support the yoke bars in position while installing the retainers.

1. Install interlock balls, detent balls and springs in the following sequence;

A. Position (3) balls in the reverse light switch bore.

B. Install reverse detent spring and ball.

C. Position (2) balls in adjacent cross bore.

D. Repeat steps B and C for 1st-2nd position, 3rd-4th position, and 5th-6th position.

NOTE: Balls and springs can be used interchangeably.

2. Position reverse yoke in housing assembly as shown.

3. Install the interlock pin in 1st-2nd yoke assembly.

4. Position 1st-2nd yoke in housing assembly.

5. Install the interlock pin in 3rd-4th yoke assembly.

6. Position 3rd-4th yoke in housing assembly.

7. Position 5th-6th shift block in housing assembly.

8. Install the middle retainer capscrews.

NOTE: It may be necessary to support rails in proper position while installing retainer.

•

Share