1

/

of

4

Uploader

Hino Truck 2011, 2012 and 2013 Service Manual Workshop Guide

Hino Truck 2011, 2012 and 2013 Service Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

HINO 238, 258LP, 268, 338, 358

Format: PDF

Language: English

Hino 2011, 2012 and 2013 Truck Manual for 238, 258LP, 268, 338, 358 – 1097 Pages

Hino 2011, 2012 and 2013 ECU and BCU Manual – 926 Pages

Hino J08E-VB and J08E-VC Engine Manual – 329 Pages

Description

Hino Truck 2011, 2012 and 2013 Series: 238, 258LP, 268, 338, 358 Service Manual

This is the Repair and Service Manual for

Hino Truck

2011, 2012 and 2013

HINO 238, 258LP, 268, 338, 358

Format: PDF

Language: English

Hino 2011, 2012 and 2013 Truck Manual for 238, 258LP, 268, 338, 358 – 1097 Pages

Hino 2011, 2012 and 2013 ECU and BCU Manual – 926 Pages

Hino J08E-VB and J08E-VC Engine Manual – 329 Pages

This workshop manual has been prepared to provide information covering repairs on 238, 258LP, 268, 338, 358 series Hino 2011, 2012 and 2013 trucks.

To use Hino 2011, 2012 and 2013 trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

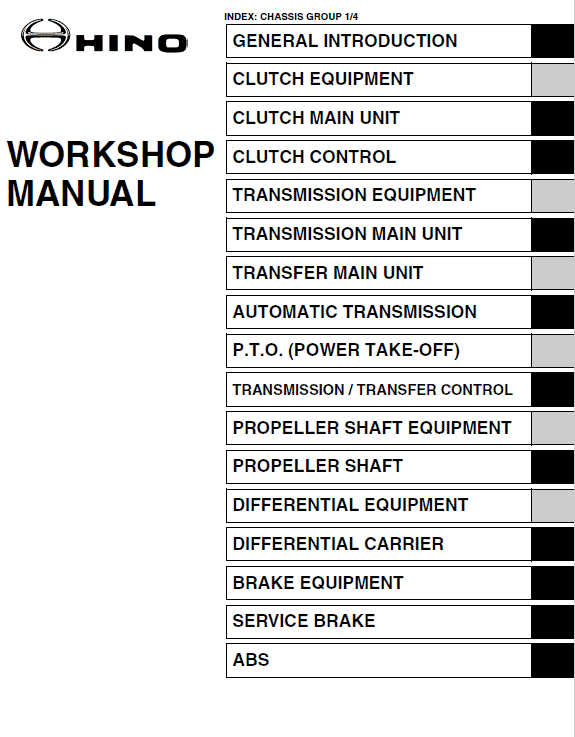

Table of Content For Hino 2011, 2012 and 2013 Truck Manual:

General Introduction

Clutch Equipment

Clutch Main Unit

Clutch Control

Transmission Equipment

Transmission Main Unit

Transfer Main Unit

Automatic Transmission

P.t.o. (Power Take-off)

Transmission / Transfer Control

Propeller Shaft

Differential Equipment

Differential Carrier

Propeller Shaft Equipment

Brake Equipment

Service Brake

Abs & Asr

Es Start (Easy & Smooth Start) System

Exhaust Brake

Retarder Brake

Parking Brake

Steering Equipment

Steering Unit

Power Steering

Axle Equipment

Front Axle

Rear Axle

Wheel & Tire

Suspension Equipment

Suspension

Chassis Equipment

Chassis Frame

Coupler (5th Wheel)

Pintle Hook

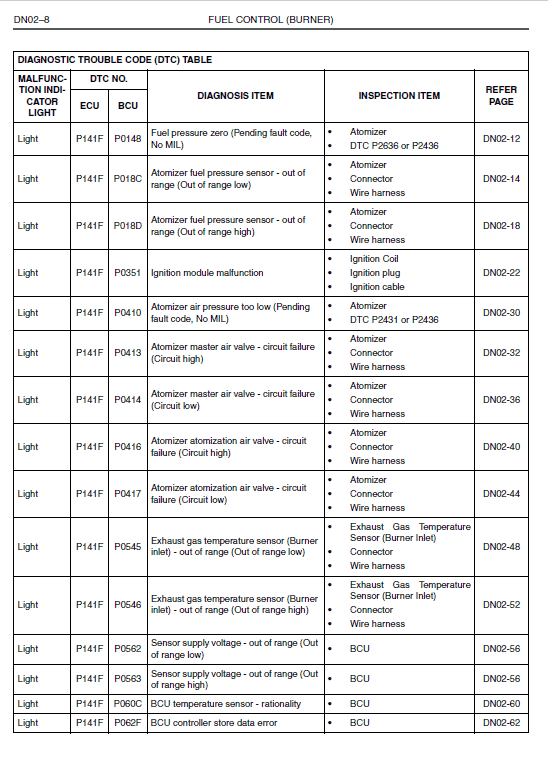

Engine Control

Fuel Control

Brake Control

Suspension Control

CAB Equipment Control

Others

Hino Truck 2011, 2012, 2013 Manual Instruction Extract:

3. BRAKE PADS

(1) Inspect the rotor for scoring, warping, cracks, bluing, heat spots or other damage or defects and minimum thickness. Repair or replace if necessary.

(2) Inspect the disc brake calipers for leakage, damage or defects to piston boots, seals or pistons. Replace or repair the parts as required.

(3) Clean and inspect the lining rail covers. If they are worn, they must be replaced.

NOTICE

The inboard and outboard brake pads are identical, except when they are equipped with a mechanical wear sensor.

(4) Install the brake pads. Ensure that the friction surface is against the rotor. Install the pad retainer spring and tighten the bolt to 30 lb-ft (40 Nm) of torque.

NOTICE

Brake pad clearance adjustment is automatic.

(5) Fill the master cylinder reservoir with new, clean, high-performance DOT 3 brake fluid or equivalent. Make several brake applications to move the brake pistons and linings out into contact with the brake rotors.

(6) Recheck master cylinder reservoir and top off as necessary to manufacturer's recommended level.

(7) Bleed the brake system.

(8) Install the tire and wheel assembly according to the manufacturer's instructions.

(9) Lower the vehicle and road test for correct operation.

4. ASSEMBLE THE SUPPORT

(1) Install the support mounting bolts. Tighten the bolts to the specified torque. Refer to Section 8.

(2) Install the ABS sensor. Tighten the bolt to 8 lb-ft (11 Nm).

(3) Install the hub and rotor assembly according to vehicle manufacturer's recommended service procedure.

(4) Install the splash shield, if equipped.

(5) Install the caliper as described in Caliper in this section.

Share