1

/

of

4

Uploader

Hino Truck 2018 COE HEV Service Manual Workshop Guide

Hino Truck 2018 COE HEV Service Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Hino 2018 COE HEV Truck Manual for 155, 155h, 195, 195h Series – 890 Pages

Hino 2018 Owners Manual – 424 Pages

Troubleshooting Manual for Hino 2017 COE HEV – 886 Pages

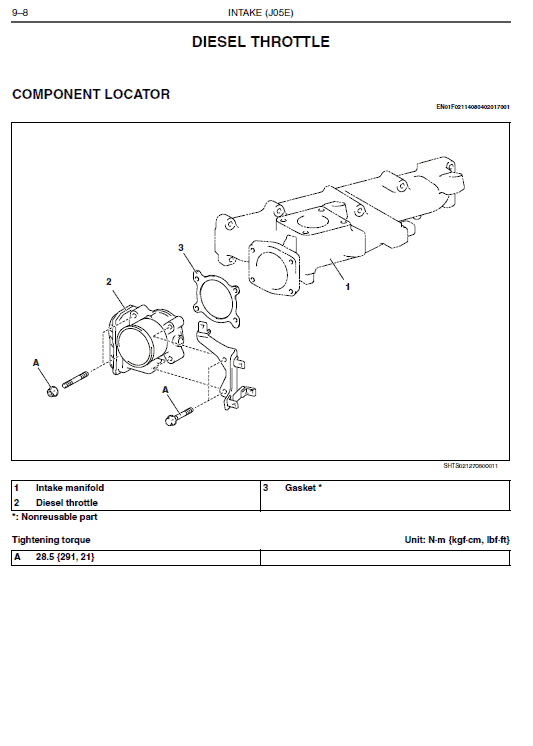

Hino J05E Engine Manual – 668 Pages

Description

Hino Truck 2018 COE HEV Service Manual

This is the Repair and Service Manual for

Hino Truck

2018 COE HEV

Applicable for HINO 155, 155h, 195, 195h series,

Format: PDF

Language: English

Hino 2018 COE HEV Truck Manual for 155, 155h, 195, 195h Series – 890 Pages

Hino 2018 Owners Manual – 424 Pages

Troubleshooting Manual for Hino 2017 COE HEV – 886 Pages

Hino J05E Engine Manual – 668 Pages

This workshop manual has been prepared to provide information covering repairs on 155, 155h, 195, 195h Series Hino 2018 COE HEV trucks.

To use Hino Year 2018 and Series 155, 155h, 195, 195h Conventional trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

Table of Content For Hino 2018 COE HEV Truck Manual:

General Introduction

Engine

Hybrid System

Transmission

Clutch

Propeller Shaft

Axle

Differential

Brake

Steering

Frame and Frame Accessory

Cab Mounting and Cab Suspension

Body Construction

Suspension

Body Inside Accessory

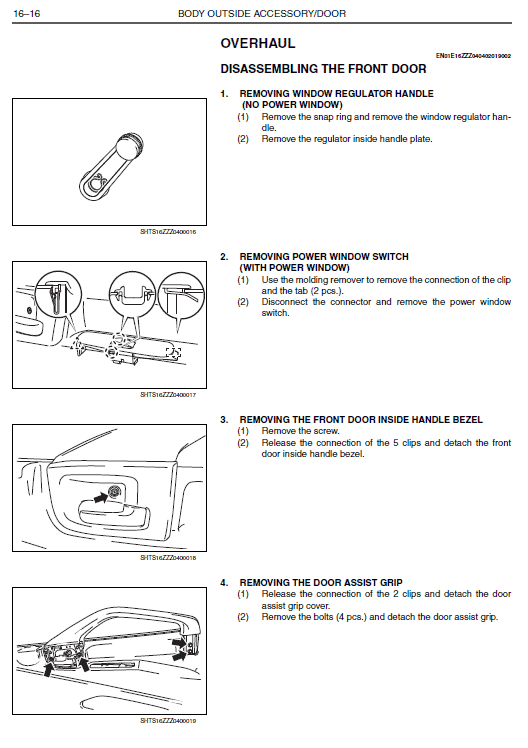

Body Outside Accessory

Air Bag and Seat Belt

Heater and Air Conditioner

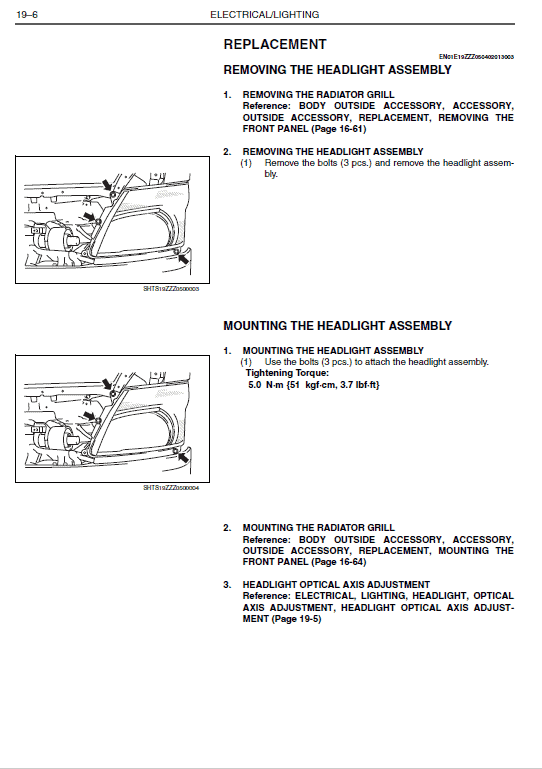

Electrical

Control System

Hino Truck 2018 COE HEV Manual Instruction Extract:

INSPECTING THE DIFFERENTIAL CARRIER ASSEMBLY

1. INSPECTING THE SIDE GEAR AND RING GEAR.

(1) Inspect the side gear and ring gear for wear and damage. If any defect is found, replace the part.

NOTICE

When replacing the ring gear, replace the drive pinion of the drive pinion assembly as a set.

2. INSPECTING THE DIFFERENTIAL SPIDER (1) Using a micrometer, measure the outer diameter of the differential spider.

(2) Using a dial caliper gauge, measure the inner diameter of the differential pinion.

(3) Subtract the differential spider outer diameter from the differential pinion inner diameter to compute the gap. If it exceeds the limit,replace the differential spider and the differential pinion.

5. INSPECTING THE BACKLASH BETWEEN

THE DIFFERENTIAL PINIONS AND SIDE GEARS

(1) Install the side gear thrust washers No.1 and the side gears onto the left hand side differential case.

(2) Install the differential pinions (4 pcs.) and the pinion thrust washers (4 pcs.) to the differential spider.

(3) Install the differential spider, assembled with the differential pinions and pinion thrust washers, onto the left hand side differential case.

(4) As shown in the figure, set the dial gauge onto the left hand side differential case.

(5) Measure the backlash when the side gear and differential pinion are in position as shown in the figure.

(6) If the measurement exceeds the standard value, replace the parts.

(7) Using the same method, measure the backlash between the side gears and the differential pinions on the right hand side differential case side.

Share