1

/

of

4

Uploader

Hino Truck 2018 Conventional Service Manual Workshop Guide

Hino Truck 2018 Conventional Service Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Format: PDF

Language: English

Hino 2018 Conventional Truck Manual for 238, 258LP, 268, 338 Series – 1010 Pages

Hino 2018 Conventional Owners Manual – 552 Pages

Troubleshooting Hino 2018 Manual – 626 Pages

Hino J08E-VB and J08E-WU Engine Manual – 353 Pages

Description

Hino Truck 2018 Conventional Service Manual

This is the Repair and Service Manual for

Hino Truck

2018

Applicable for 238, 258LP, 268, 338 Series –

Format: PDF

Language: English

Hino 2018 Conventional Truck Manual for 238, 258LP, 268, 338 Series – 1010 Pages

Hino 2018 Conventional Owners Manual – 552 Pages

Troubleshooting Hino 2018 Manual – 626 Pages

Hino J08E-VB and J08E-WU Engine Manual – 353 Pages

This workshop manual has been prepared to provide information covering repairs on 238, 258LP, 268, 338 Series Hino 2018 Conventional trucks.

To use Hino 2018 Conventional trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

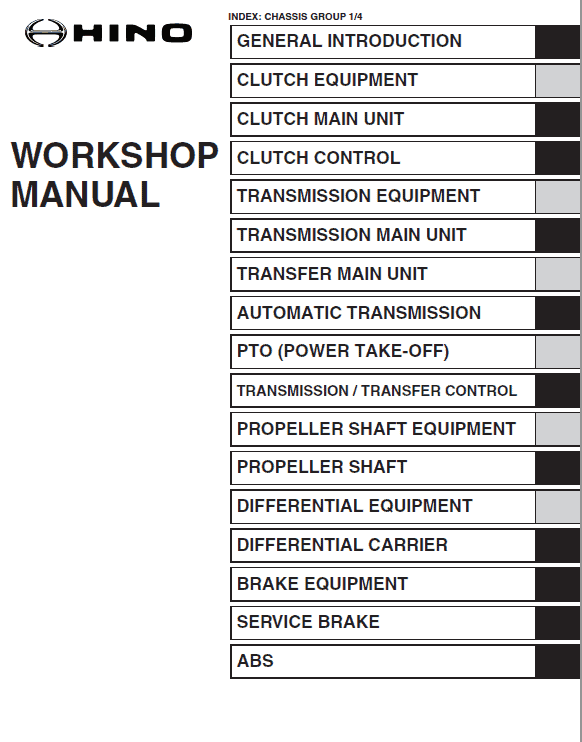

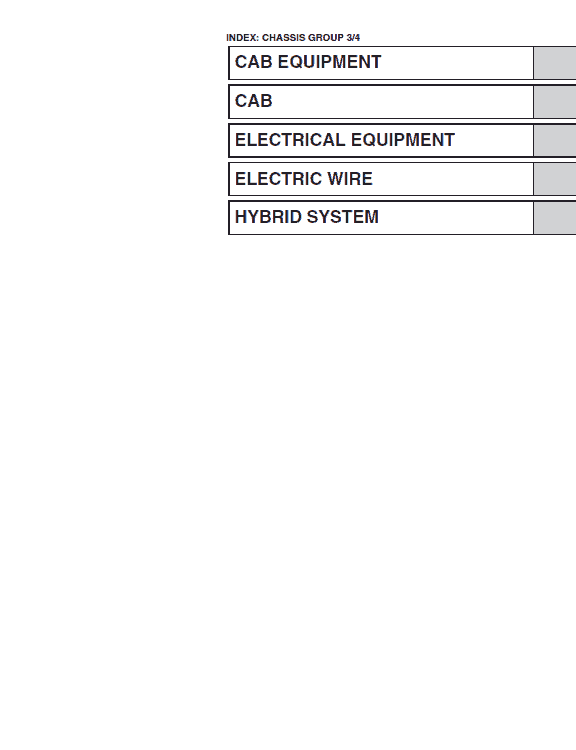

Table of Content For Hino 2018 Conventional Truck Manual:

General Introduction

Clutch Equipment

Clutch Main Unit

Clutch Control

Transmission Equipment

Transmission Main Unit

Transfer Main Unit

Automatic Transmission

P.t.o. (Power Take-off)

Transmission / Transfer Control

Propeller Shaft

Differential Equipment

Differential Carrier

Index: Chassis Group 1/4

Propeller Shaft Equipment

Brake Equipment

Service Brake

Abs & Asr

Es Start (Easy & Smooth Start) System

Exhaust Brake

Retarder Brake

Parking Brake

Steering Equipment

Steering Unit

Power Steering

Axle Equipment

Front Axle

Rear Axle

Wheel & Tire

Suspension Equipment

Suspension

Chassis Equipment

Chassis Frame

Coupler (5th Wheel)

Pintle Hook

Hino Truck 2018 Conventional Manual Instruction Extract:

Symptom

Possible cause

Remedy/Prevention

No Braking Effect or Excessive Pedal Travel

Reservoir fluid level low

Check for causes of fluid leak, repair as required and refill the reservoir. Bleed the system as needed.

Air in the hydraulic system

Bleed the system.

Bleed screw loose or open

Bleed the system and tighten the bleed screw.

Caliper piston seal damaged

Disassemble the caliper and replace the piston seals. Replace the piston if it is damaged.

Excessive rotor runout or bent rotor

Check the rotor with a dial indicator. Install a new rotor if the runout exceeds the maximum specified.

Worn or excessively loose wheel bear- ings

Adjust or needed replace the bearings

Low quality brake fluid

Drain and clean the system. Replace with the recommended brake fluid.

Weak brake hose that expands under pressure

Replace the hoses.

Brake Noise (Chatter)

Excessive lateral runout of rotor

Check the runout with a dial indicator. Install a new rotor if the runout exceeds the maximum specified.

Lack of rotor parallelism

Check the parallelism with a microme- ter. Resurface or install a new rotor as required.

Loose wheel bearing

Readjust the bearing to the specified torque.

Brake Noise (Scraping)

Rust or mud build-up on edges of rotor and on caliper housing

Clean or replace as necessary.

Worn pad or pad installed backward

Replace the pads in the axle sets only with the friction surface against the rotor.

Incorrect caliper alignment permitting rotor to scrape on housing

Correct the alignment.

Brake Noise (Groan)

Pressure on the brake pedal too light

Slightly increase the pedal effort to eliminate the noise.

Brake Noise (Rattle)

Excessive clearance between the shoe and caliper

Install new pads.

Pad retainer spring missing or not cor- rectly positioned

Install a new pad retainer spring or position it correctly.

Brake Noise (Squeal)

Glazed pads

Resurface or replace the pads in the axle sets only.

Weak pad retainer spring

Install a new pad retainer spring.

Pad wear indicator contacting rotor

Install new pads in the axle sets only.

Foreign material embedded in linings

Replace the pads in the axle sets only.

Share