1

/

of

4

Uploader

Hino Truck FA4J, FB4J Year 2003 Repair Manual (FA, FB) Workshop Guide

Hino Truck FA4J, FB4J Year 2003 Repair Manual (FA, FB) Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

This is the Repair and Service Manual for

Hino Truck

2003

Series: FA, FB

Format: PDF

Language: English

Hino 2003 Truck FA and FB Series Manual – 1104 Pages

Hino Truck 2003 Owners Manual – 330

Description

Hino Truck FA4J, FB4J Year 2003 Repair Manual (FA, FB)

This is the Repair and Service Manual for

Hino Truck

2003

Series: FA, FB

Format: PDF

Language: English

Hino 2003 Truck FA and FB Series Manual – 1104 Pages

Hino Truck 2003 Owners Manual – 330

This workshop manual has been prepared to provide information covering repairs on FA, FB series Hino 2003 trucks.

To use Hino 2003 trucks for years, smoothly, safely, and economically without trouble, it is important to perform inspections.

Maintenance required to be performed is the responsibility of the owner. Some recommended repairs of your truck are mentioned. When making any repair of your truck, be careful not to be injured through improper procedures.

As for maintenance items, refer to the Owners and Drivers Manual. All information and specifications in this manual are based upon the latest product information available at the time of printing.

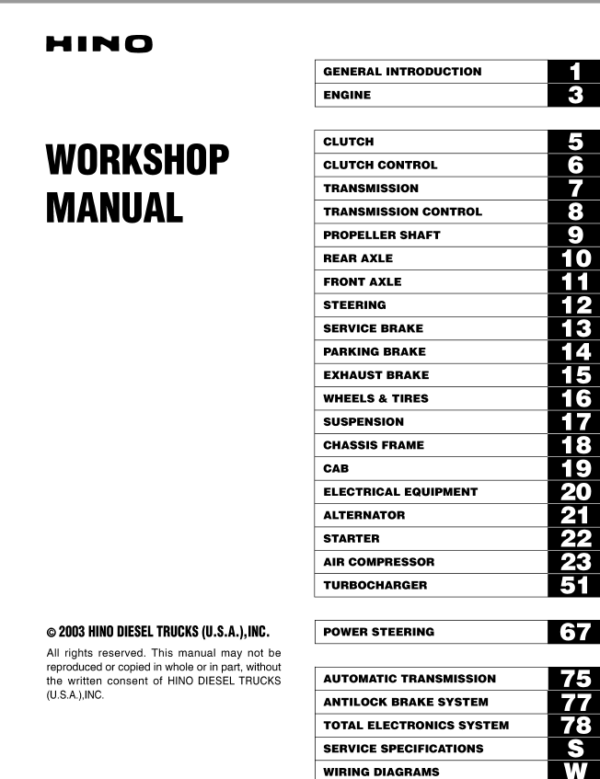

Table of Content For Hino 2003 Truck Manual:

General Introduction

Engine

Clutch

Clutch Control

Transmission

Transmission Control

Propeller Shaft

Rear Axle

Front Axle

Steering

Service Brake

Parking Brake

Exhaust Brake

Wheels & Tires

Suspension

Chassis Frame

Cab

Electrical Equipment

Alternator

Starter

Compressor

Turbocharger

Spring Brake

Power Steering

Automatic Transmission

Antilock Brake System

Total Electronics System

Service Specification

Electrical Wiring Diagrams

Hino Truck 2003 Manual Instruction Extract:

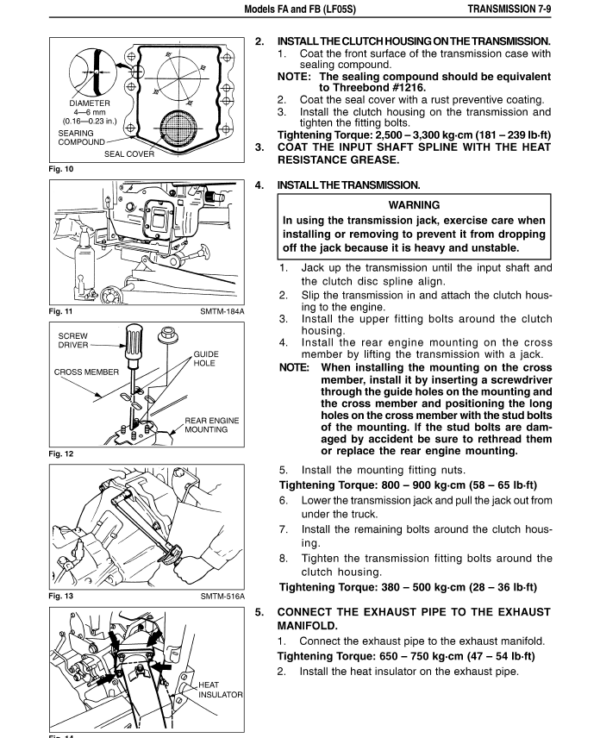

ASSEMBLY

NOTE: Prior to assembly, be sure to apply engine oil to each sliding part and replace the O-rings and gaskets with new ones.

1. ASSEMBLE THE INLET VALVE.

1. Assemble the gasket, valve seat, inlet valve and valve spring in that order from the lower side of the cylinder head, then install the valve holder and tighten provisionally.

2. Before completely tightening the valve holder, push in the inlet valve with a finger or bar from the upper side of cylinder head (unloader valve side), and check that the valve and spring moves smoothly.

3. After checking the operation of the valve and spring, tighten the valve holder to the specified torque using a special tool.

Special Tool: Adapter (09481 – 1090) Tightening Torque: 1,000 – 1,200 kg-cm (73 – 86 lb-ft)

4. Check to see that the inlet valve stroke is approximately 2.5 mm (0.098 in.).

5. Caulk three places on the outer periphery of the valve holder.

NOTE: In this case, be sure that the lower face of the valve holder is not protruding from the head lower face. (The faces should be flush or the lower face of the valve holder should be recessed from the head lower face.)

Share