1

/

of

4

Uploader

Komatsu HM350-2 Dump Truck Service Manual Workshop Guide

Komatsu HM350-2 Dump Truck Service Manual Workshop Guide

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Shop Manual:

1448 pages & 1462 pages (Covering all Serial numbers)

Operation and Maintenance Manual:

300 pages

Specifications:

Brand:

Komatsu

Model:

HM350-2

Serial Number:

A11001 and up

Type:

Dump Truck

Manuals:

Shop Manual and Operation and Maintenance Manual

Publication Number:

SEN00238-4, CEBM007801 and CEAM017704

Language:

English

Format:

PDF

Description

Table of Contents

00 Index and foreword

01 Specification

10 Structure, function and maintenance standard

20 Standard value table

30 Testing and adjusting

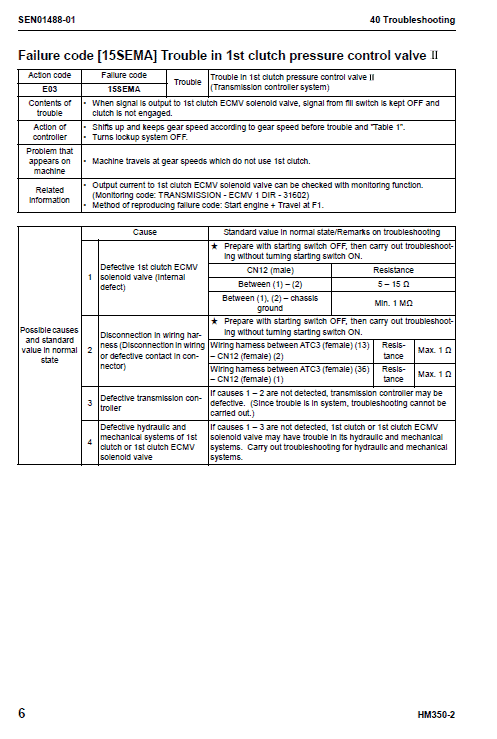

40 Troubleshooting

50 Disassembly and assembly

90 Diagrams and drawings

GENERAL

This section lists the general machine dimensions, performance specifications, component weights, and fuel, coolant and lubricant specification charts.

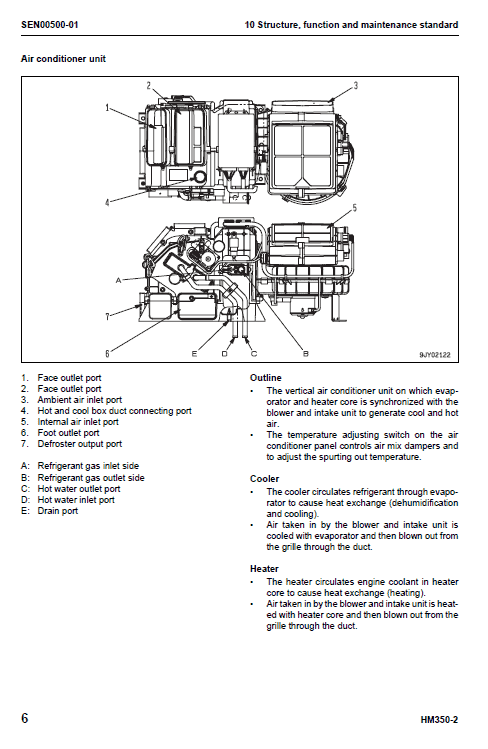

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING, ADJUSTING AND TROUBLESHOOTING KOMATSU Dump Truck HM350-2

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating Problems to Causes are also mention in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, disassembling or assembling each component, as well as precautions to be taken for these operations.

Disassembly and assembly of output shaft assembly

Disassembly

1. Oil cage assembly

Remove oil seal (1) from cage (2).

2. Cover assembly

Remove bearing (3) from cover (4).

3. Damper assembly (5)

1) To keep the balance when reassembling, mark the set positions of flange (6), body assembly (7), and outer body (9) before disassembling.

2) Remove body assembly (7) and rubber (8) from outer body (9).

3) Remove bearing (10) from flywheel.

Share