1

/

of

4

Uploader

Komatsu PC158US-2 Excavator Service Manual Workshop Guide

Komatsu PC158US-2 Excavator Service Manual Workshop Guide

Regular price

$33.50 USD

Regular price

Sale price

$33.50 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Shop Manual:

521 pages

Specifications:

Brand:

Komatsu

Model:

PC158US-2

Type:

Excavator

Serial Number:

10001 and up

Manuals:

Shop Manual

Publication:

SEBM026504

Language:

English

Format:

PDF

Description

Table of Contents

01 GENERAL ……………………………………………………………………………………………… 01-1

10 STRUCTURE AND FUNCTION ………………………………………………….. 10-1

20 TESTING AND ADJUSTING ………………………………………………………. 20-1

30 DISASSEMBLY AND ASSEMBLY …………………………………………….. 30-1

40 MAINTENANCE STANDARD ……………………………………………………… 40-1

90 OTHERS ………………………………………………………………………………………………… 90-1

GENERAL

This section lists the general machine dimensions, performance specifications, component weights, and fuel, coolant and lubricant specification charts.

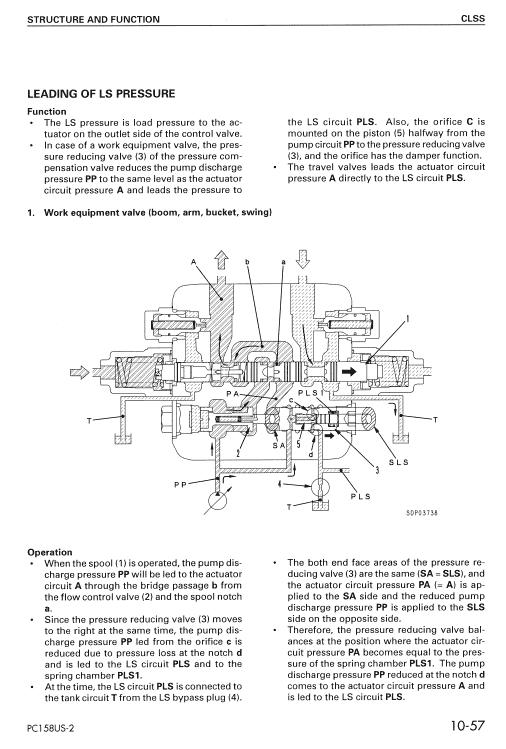

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

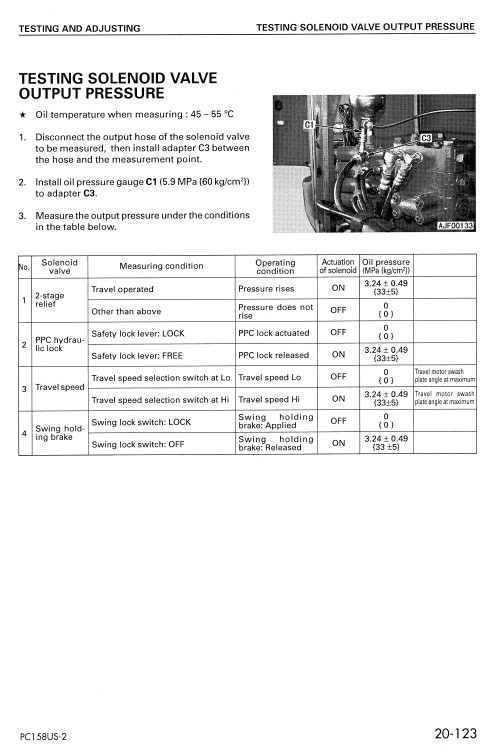

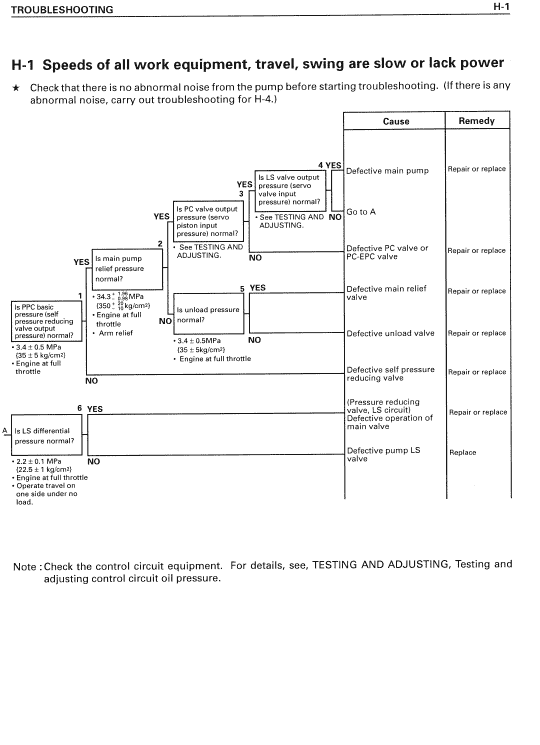

TESTING, ADJUSTING AND TROUBLESHOOTING

This section explains checks to be made before and after performing repairs, as well as adjustments to be made at completion of the checks and repairs. Troubleshooting charts correlating Problems to Causes are also mention in this section.

DISASSEMBLY AND ASSEMBLY

KOMATSU Excavator PC158US-2

This section explains the order to be followed when removing, installing, disassembling or assembling each component, as well as precautions to be taken for these operations.

When raising heavy components, use a hoist or crane. Check that the wire rope, chains and hooks are free from damage.

Always use lifting equipment which has ample capacity. Install the lifting equipment at the correct places. Use a hoist or crane and operate slowly to prevent the component from hitting any other part. Do not work with any part still raised by the hoist or crane.

•

MANUAL EXTRACT – ASSEMBLY OF TRACK ROLLER

1. Using push tool (D, press fit bushings (9) and (10) to roller (4).

2. Assemble collar (8) to shaft (5).

3. Using tool M1, install floating seal (6) to shaft (5). * When assembling the floating seal, clean the contact surface of O-ring (6c) and floating seal (6a), remove all grease and oil, and dry it. Make sure that no dirt or dust sticks to the contact surface of the floating seal.

4. Using tool M1, install floating seals (6) and (3) to roller (4). * For details of the precautions when installing floating seals (6b) and (6d), and (3b) and (3d), see the precautions marked * for Step 3.

5. Assemble shaft (5) to roller (4).

6. Turn over roller (4) and shaft (5) assembly.

7. Using tool M1, install floating seal (3) to collar (2). * For details of the precautions when installing floating seals (3a) and (3c), see the precautions marked * for Step 3.

8. Assemble collar (2) to shaft (5), and install pin (1 ).

Share