1

/

of

4

Uploader

Kubota L4100 Tractor Service Manual

Kubota L4100 Tractor Service Manual

Regular price

$33.00 USD

Regular price

Sale price

$33.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Kubota L4100 Tractor Workshop Manual – 346 Pages

Format: PDF

Publication: 9Y111-02781

Language: English

Description

Kubota L4100 Tractor Workshop Service Manual

Kubota

Tractor

Model L4100

Format: PDF

Publication: 9Y111-02781

Language: English

Kubota L4100 Tractor Workshop Manual – 346 Pages

Table of Content of the Workshop Service Manual

This Workshop Manual tells the servicing personnel about the mechanism, servicing and maintenance of the L4100. It contains 4 parts: "Information", "General", "Mechanism" and "Servicing".

– Information

This section contains information below.

• Safety First

• Safety Label

• Specification

• Dimension

– General

This section contains information below.

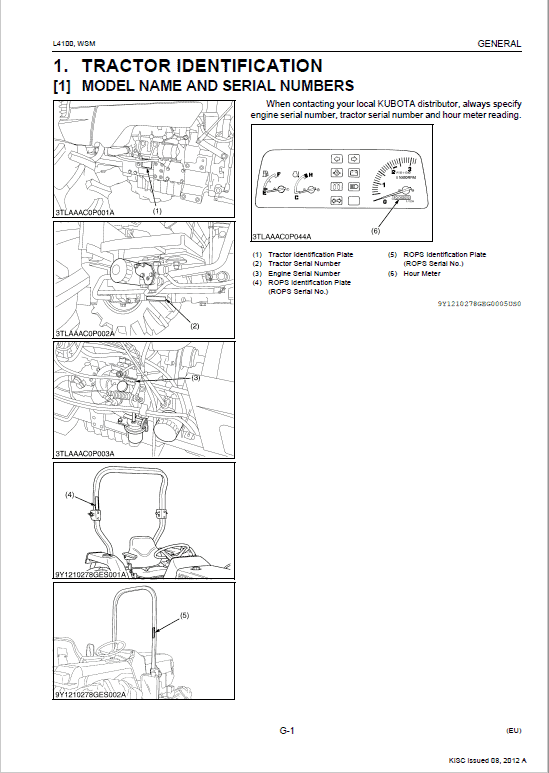

• Engine Identification

• Model Identification

• General Precautions

• Maintenance Check List

• Check and Maintenance

• Special Tools

– Mechanism

This section contains information on the structure and the function of the unit. Before you continue with the subsequent sections, make sure that you read this section.

Refer to the latest version of Workshop Manual for the diesel engine / tractor mechanism that this workshop manual does not include.

– Servicing

This section contains information below.

• Troubleshooting

• Servicing Specifications

• Tightening Torques

• Checking, Disassembling and Servicing

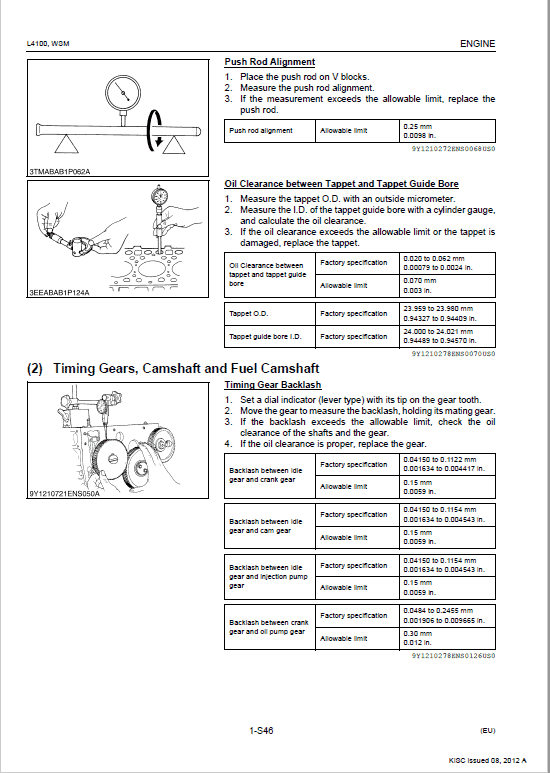

Manual Extract – Oil Clearance between Crankpin and Crankpin Bearing

1. Clean the crankpin and crankpin bearing.

2. Put a strip of plastigauge on the center of the crankpin.

3. Install the connecting rod cap and tighten the connecting rod screws to the specified torque, and remove the cap again.

4. Measure the amount of the flattening with the scale, and get the oil clearance.

5. If the oil clearance exceeds the allowable limit, replace the crankpin bearing.

6. If the same size bearing is useless because of the crankpin wear, replace it with an undersize one referring to the table and figure.

NOTE

• Never insert the plastigauge into the crankpin oil hole.

• Be sure not to move the crankshaft while the connecting rod screws are tightened.

Share