1

/

of

4

Uploader

Liebherr L506, L508, L510 Wheel Loader Service Manual

Liebherr L506, L508, L510 Wheel Loader Service Manual

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

L 506 from serial 101 (Type 371)

L 508 from serial 101 (Type 232 and 372)

L 510 from serial 101 (Type 340)

Language: English

Publication: 8145017

Format: PDF

February 1991

Liebherr L506, L508, L510 Wheel Loader Service Manual – 550 Pages

Description

Liebherr L506, L508, L510 Wheel Loader Manual

Wheel Loader

Applicable Model :

L 506 from serial 101 (Type 371)

L 508 from serial 101 (Type 232 and 372)

L 510 from serial 101 (Type 340)

Language: English

Publication: 8145017

Format: PDF

February 1991

Liebherr L506, L508, L510 Wheel Loader Service Manual – 550 Pages

Table of Content of the Service Manual:

General

Special Tools

Lubricants

Technical Data- Inspection Plans

Engine

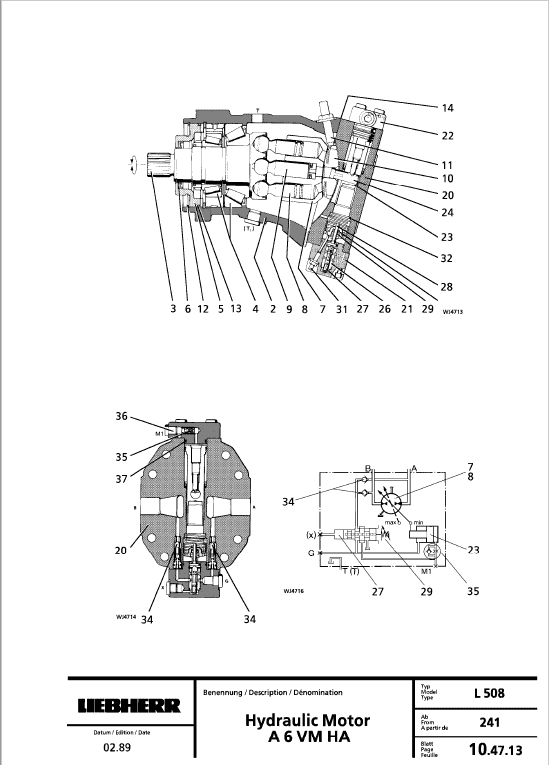

Travel Hydraulic

Working Hydraulic

Electrical System

Heating, Air conditioning System

Travel Gear

Axles

Steering

Brakes

Main Frame / Cab

Hoist Frame / Accessories

Special Installations

This manual has been issued to provide you with technical information on design, function, disassembly, assembly, adjustments and troubleshooting of components and assemblies on the LIEBHERR wheel loader.

The descriptions are brief but precise, with photographs, drawings, electric and hydraulic circuit schematics and graphic diagrams. This information is intended to simplify any necessary repair work on the LIEBHERR wheel loader.

We deliberately avoided full photographic details of each repair stage, since only skilled mechanics, already familiar with most repair work, should perform these repairs. This manual also contains information about adjustments and adjustment values.

ADJUSTMENT PROCEDURE – CHECKING AND ADJUSTING THE TRAVEL HYDRAULICS

1.1 Please note that during the warranty period only authorized LIEBHERR representatives are permitted to work on the wheel loader valves. This includes adjustment.

1.2 The valves must be checked and adjusted with the hydraulic oil at operating temperature of 60° + 10°C (140° F).

1.3 Use glycerine filled pressure gauges with an accuracy of ± 1 % . 1.4 If specified values cannot be reached, the cause must be determined according to the troubleshooting chart, and the defect must be repaired.

1.5 To check and adjust the following valves, check if the inching device on regulator valve 32 is in neutral position. See section 10.72.

1.6 After the valves have been adjusted, install new safety caps. This will prevent unauthorized personnel from attempting to adjust the valves.

Share