1

/

of

4

Uploader

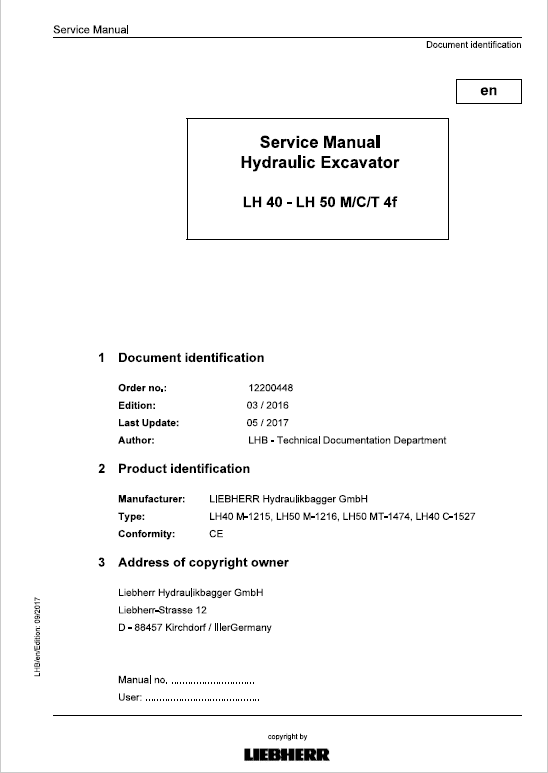

Liebherr LH40C, LH40M, LH50M, LH50MT Tier 4F Excavator Service Manual

Liebherr LH40C, LH40M, LH50M, LH50MT Tier 4F Excavator Service Manual

Regular price

$35.00 USD

Regular price

Sale price

$35.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

LH 40 C (4f) 68926 and Up ( Type 1527)

LH 40 M (4f) 68077 and Up ( Type 1215)

LH 50 M (4f) 77584 and Up ( Type 1216)

LH 50 MT (4f) 78430 and Up ( Type 1474)

Language: English

Publication: 12200448

Format: PDF

July 2017

Liebherr LH40C, LH40M, LH50M, LH50MT Tier 4F Excavator Service Manual – 1677 Pages

Operator's manual – 400 Pages

Description

Liebherr LH40C, LH40M, LH50M, LH50MT Tier 4F Excavator Service Manual

Excavator

Model :

LH 40 C (4f) 68926 and Up ( Type 1527)

LH 40 M (4f) 68077 and Up ( Type 1215)

LH 50 M (4f) 77584 and Up ( Type 1216)

LH 50 MT (4f) 78430 and Up ( Type 1474)

Language: English

Publication: 12200448

Format: PDF

July 2017

Liebherr LH40C, LH40M, LH50M, LH50MT Tier 4F Excavator Service Manual – 1677 Pages

Operator's manual – 400 Pages

Table of Content of the Service Manual:

Introduction

Technical data

Maintenance

Drive group

Cooling system

Working hydraulics

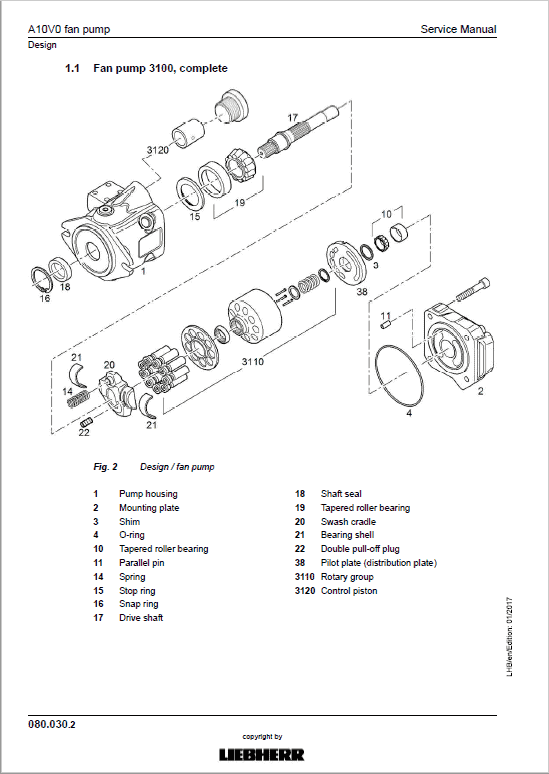

Hydraulic components

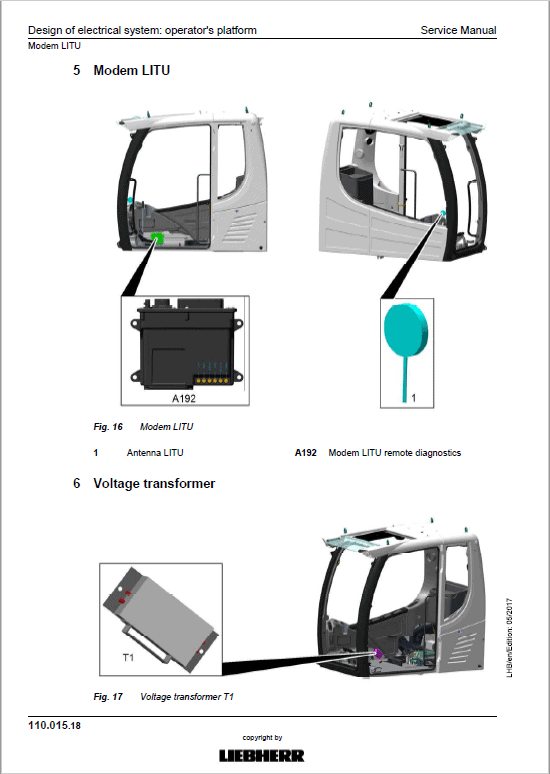

Electrical system

Travel gearbox

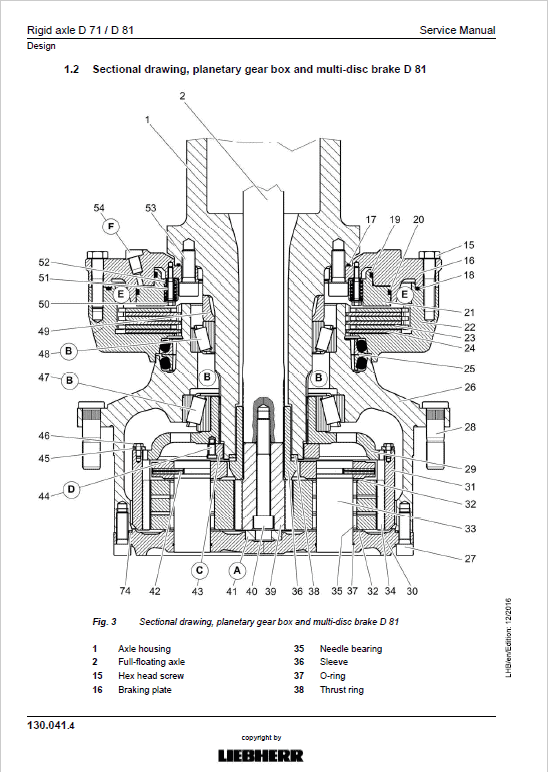

Travel gear

Steel parts of the basic machine

Working attachment

Operator's cab, heating and air conditioning

Lubrication system

Slewing gearbox and slewing ring

This manual contains technical data, design and functional descriptions as well as instructions for the operation and the adjustment of machine settings. The document includes a number of drawings, functional schematics and detailed views of units and assemblies of Liebherr hydraulic excavators.

The documentation has been designed to support customer support services, but does of course not replace proper technical training and qualification of the user, and participation in Liebherr operator training courses.

General basic technical information is not included in this manual. For operating instructions and information on spare parts, please refer to the separate documentation.

Clamping nuts are used to secure pins with pin tabs and anti-torsion elements.

Pins secured in this way prevent bending of the bearing covers (e.g. bearing covers at the swivelling arm, the boom and the stick), improve the stability of the machine and can withstand higher loads.

If clamping nuts are tightened too much, the following might result:

– Bearing covers might become bent backwards

– Welded seams might break

– Excessive friction between the connected steel components

– Increased wear

– Damage to bearing

Share