1

/

of

4

Uploader

Liebherr R954, R954B, R954C, R964, R964B, R974B Litronic Excavator Service Manual

Liebherr R954, R954B, R954C, R964, R964B, R974B Litronic Excavator Service Manual

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

R954, R954-HD, R954-V Litronic from serial 101 (Type 406, 494, 629, 630)

R964, R964-HD Litronic from serial 101 (Type 407, 610)

R974, R974B Litronic from serial 1001 (Type 408)

Language: English

Publication: 8503312

Format: PDF

July 2005

Liebherr R954, R954B, R954C, R964, R964B, R974B Litronic Wheel Excavator Service Manual – 1682 Pages

Description

Liebherr R954, R954B, R954C, R964, R964B, R974B Litronic Wheel Excavator Manual

Excavator

Model Applicable from :

R954, R954-HD, R954-V Litronic from serial 101 (Type 406, 494, 629, 630)

R964, R964-HD Litronic from serial 101 (Type 407, 610)

R974, R974B Litronic from serial 1001 (Type 408)

Language: English

Publication: 8503312

Format: PDF

July 2005

Liebherr R954, R954B, R954C, R964, R964B, R974B Litronic Wheel Excavator Service Manual – 1682 Pages

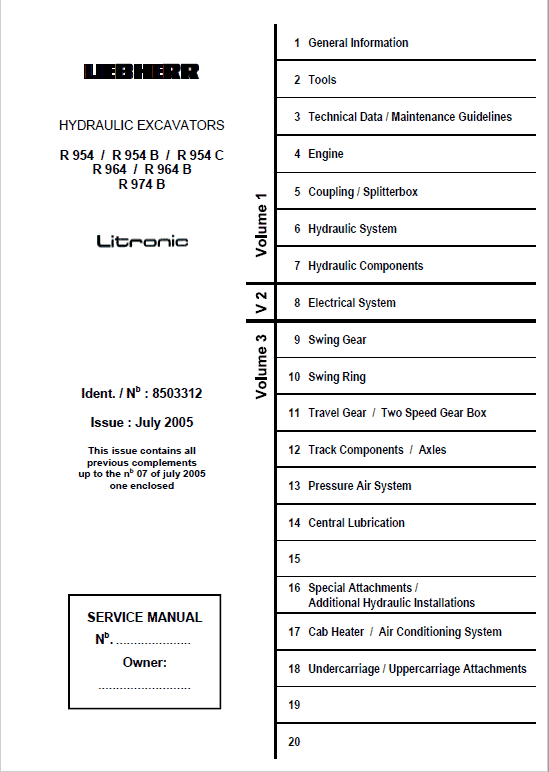

Table of Content of the Service Manual:

1 General information

2 Tools

3 Technical data / Maintenance guidelines

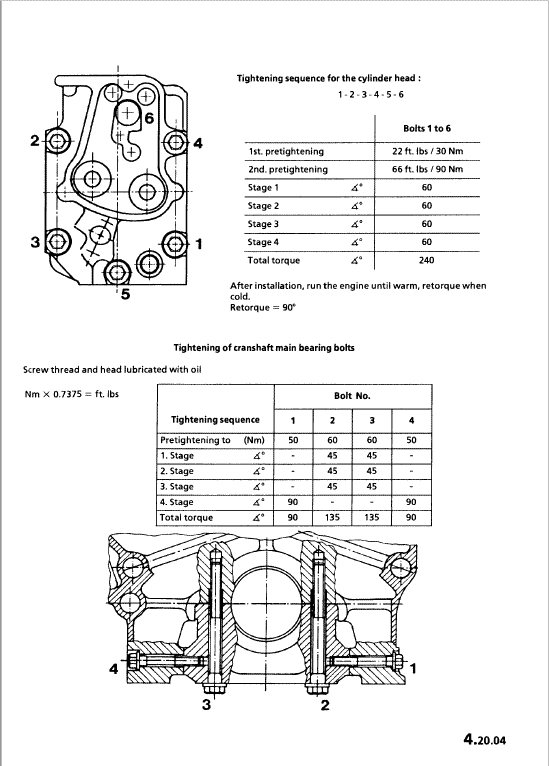

4 Engine

5 Coupling / Splitterbox

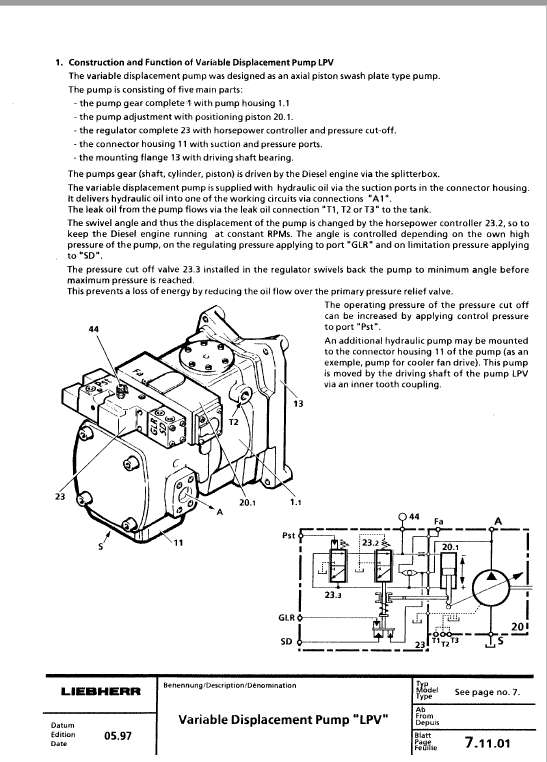

6 Hydraulic system

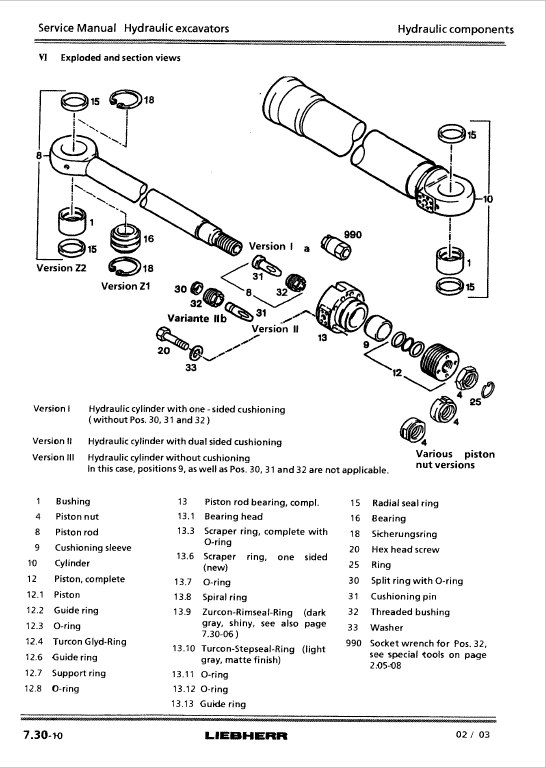

7 Hydraulic components

8 Electrical system

9 Swing gear

10 Swing ring

11 Travel gear / Two Speed Gear Box

12 Track components / Axles

13 Pressure Air System

14 Central Lubrication

16 Special Attachments / Additional Hydraulic Installations

17 Cab Heater / Air Conditioning System

18 Undercarriage / Uppercarriage Attachments

This manual has been prepared to provide you with technical information on the design and construction of the various components which made up the LIEBHERR excavator.

Manual Extract – Working position of spool valve

If a spool valve is moved from its neutral position, the connection from pump to user is open and restricts at the same time the flow to the tank.

The pump pressure rises until it reaches the pressure on the user connection. Oil starts to flow to the user. When the spool valve moves further, the connection from pump to tank closes off and opens the connection for the returning oil from the user to the tank.

The total oil flow from the pump is now available for the user.

The movement of the spool valve depends only on the available control pressure.

This control pressure can be changed continuously depending on the movement of the appropriate joystick (see description and function of the servo control, sub group 7.41).

Due to a negative spool overlap, together with metering notches, the oil flow to the users and thus all working and travel movements, can be controlled by pistons in the control blocks The piston stroke is 15 mm per side on the NS 32, about 30% overlap and about 60% fine control. The remaining stroke is used to regain the nominal diameter.

Springs, which are installed on the upper end of the spool, return the spools to neutral position if control pressure is not available.

Internal leakages on a user connection under pressure are influenced by the overlap and the play between housing and piston. Maximum permissible leak oil, see "Control Valves -Technical Data".

Share