1

/

of

4

Uploader

Linkbelt 330LX, 350LX, 370LX Excavator Service Repair Manual Workshop Guide

Linkbelt 330LX, 350LX, 370LX Excavator Service Repair Manual Workshop Guide

Regular price

$41.00 USD

Regular price

Sale price

$41.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Service Repair Manual:

604 pages

Operators Manual:

220 pages

Hydraulic and Electrical Schematics

Specifications:

Brand:

LinkBelt

Model:

330LX, 350LX, 370LX

Applicable for also:

330 LX LF — Long Front

330 LX RB — Road Builder

330 LX TL & 330 LX TL FC — Timber Log-Loader with or without Forestry Cab.

330 LX DHP & 330 LX DHP FC — Delimber-Harvester Processor with or without Forestry Cab350 LX LF — Long Front

350 LX RB — Road Builder

350 LX TL & 350 LX TL FC — Timber Log-Loader with or without Forestry Cab.

370 LX LF — Long Front/Scrape Loader

370 LX RB — Road Builder

370 LX TL & 370 LX TL FC — Timber Log-Loader with or without Forestry Cab.

Type:

Excavator

Manuals:

Repair and Operators Manual

Publication Numbers:

1129

Language:

English

Format:

PDF

Note: Manual content only reference 330LX

Description

Table of Contents

1. General Information

Safety, General Information, and Standard Torque Data

General Specifications and Special Torque Settings

2. Engine

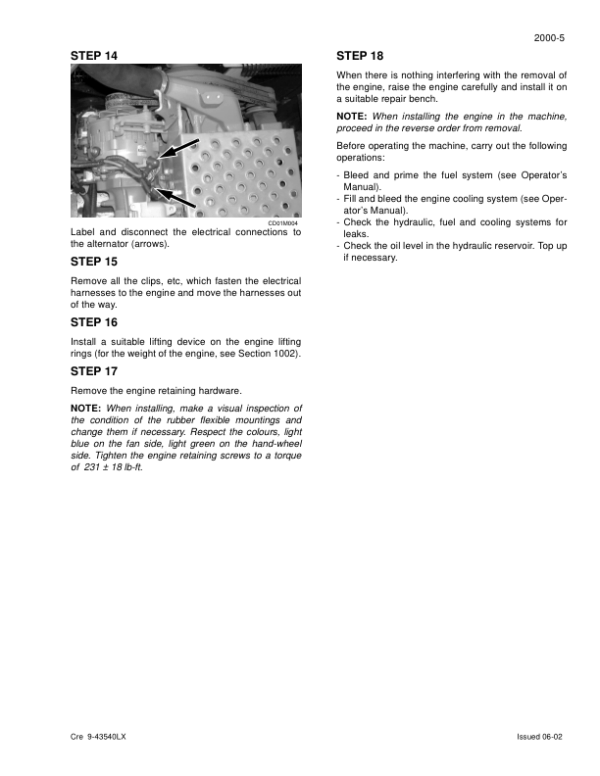

Removal and Installation of the Engine

Radiator and Oil Cooler

Engine Specifications

Disassembly and Assembly of the Engine

3. Fuel System

Fuel Tank

Fuel Engine System

4. Electrical System

Electrical System, Electrical and Electronic Troubleshooting

Inspection and Maintenance of Batteries and Connecting a Booster Battery

Main and Engine Electronic Control Boxes

5. Undercarriage

Removal and Installation of Tracks

Rollers

Sprocket

Idler Wheel and Tension Shock Absorber

6. Drive Train

Drive Motor and Final Drive Transmission Removal and Installation

Swing Reduction Gear, Removal and Installation

Swing Reduction Gear, Disassembly and Assembly

Travel Reduction Gear Assembly and Disassembly

7. Undercarriage Hydraulics

Undercarriage Hydraulics Overview

8. Upper Structure Hydraulics

Depressurizing and Decontaminating the Hydraulic System, Use of the Vacuum Pump and Bleeding the Components

Specifications, Troubleshooting, Checks, and Hydraulic Pressure Settings

Hydraulic Reservoir Removal and Installation

Main and Pilot Pumps, Removal and Installation

Main Hydraulic Control Valve, Removal and Installation

Attachment Cylinders, Removal and Installation

Hydraulic Swivel, Removal and Installation

Pilot Blocks, Removal and Installation

Swing Motor, Removal and Installation

Free Swing Disassembly and Assembly

Main Hydraulic Pump, Disassembly and Assembly (UCHIDA)

Main Hydraulic Pump, Disassembly and Assembly (KAWASAKI)

Main Hydraulic Control Valve, Disassembly and Assembly

Attachment Cylinders, Disassembly and Assembly

Hand Control Levers, Disassembly and Assembly

Foot Control Levers, Disassembly and Assembly

Six-Solenoid Valves, Disassembly and Assembly

Cushion Valve, Disassembly and Assembly

Safety Valve

Hydraulic Swivel, Disassembly and Assembly

Swing Motor, Disassembly and Assembly

Hydraulic Functions

Travel Hydraulic Motor, Disassembly and Assembly

9. Upper Structure

Upper Structure, Turntable, and Counterweight

Boom, Arm, and Bucket

Seat and Seat Belt

Cab and Cab Equipment

Large Format Hydraulic and Electrical Schematics

Share