1

/

of

4

Uploader

Linkbelt LS-1600 C2 Excavator Service Repair Manual Workshop Guide

Linkbelt LS-1600 C2 Excavator Service Repair Manual Workshop Guide

Regular price

$38.00 USD

Regular price

Sale price

$38.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Service Repair Manual:

490 pages

Operators Manual:

120 pages

Hydraulic and Electrical Schematics

Specifications:

Brand:

LinkBelt

Model:

LS 1600 C Series II

Type:

Excavator

Manuals:

Repair and Operators Manual

Publication Numbers:

789 and 790

Language:

English

Format:

PDF

Description

Table of Contents (Service Manual)

1. Caution for Inspection and Maintenance

Basic Rules

General Rules for Disassembling

Pre-Disassembly

Cautions for Disassembling

General Rules for Reassembling

After Disassembly

Cautions for Reassembly

Handling of Interchangeable (Common) Parts

Packings

O-Ring

Oil Seal

Bearing

Snap Ring

Conversion Tables

Length

Area

Volume

Mass

Pressure

Torque

Temperature

Circuit Diagrams

Hydraulic Circuit (For Blade)

Hydraulic Circuit (For Offset)

Electric Circuit

Performance Standards

Measuring Pressure

Accumulator

Hydraulic System Relief Valve Adjustment

Main Relief Pressure

Main Control Valve Port Relief Pressure

Pilot Circuit Pressure

Swing Cross Over Relief Pressure

Points to Note for Replacement of Main Hydraulic Device

Hydraulic Oil Pressure Release

Hydraulic Pump

Swing Motor

Travel Motor

Hydraulic Cylinder

2. Undercarriage

Travel Device

Removal and Installation

Drive Sprocket

Removal and Installation

Take-Up Roller

Removal and Installation

Structural Diagram

Tools and Jigs

Disassembly and Reassembly

Upper Roller

Removal and Installation

Structural Diagram

Tools and Jigs

Disassembly and Reassembly

Lower Roller

Removal and Installation

Structural Diagram

Tools and Jigs

Disassembly and Reassembly

Recoil Spring

Removal and Installation

Structural Diagram

Disassembly and Reassembly

Grease Cylinder

Removal and Installation

Structural Diagram

Tools and Jigs

Disassembly and Reassembly

Track Shoe

Removal and Installation

Structural Diagram

Exchange Procedure

Rotating Joint

Removal and Installation

3. Upper Structure

Swing Device

Removal and Installation

Engine and Radiator Mounting

Engine Installation

Radiator Installation

Hydraulic Pump

Removal and Installation

Holding Valve

Removal and Installation

Control Valve

Removal and Installation

Pilot Valve

Removal and Installation

Manifold Valve

Removal and Installation

Stack Valve

Removal and Installation

4. Attachment

Bucket Cylinder

Removal and Installation

Arm Cylinder

Removal and Installation

Boom Cylinder

Removal and Installation

Off-Set Cylinder

Removal and Installation

Blade Cylinder

Removal and Installation

5. Electrical System

Monitor System

Outline of Monitor System

Configuration of System

Monitor Display Section

Operation Indication

Removal and Installation of Monitor Display Section

Removal

Disassembly and Replacement

Installation

Battery

6. Maintenance

Hydraulic Pump

Maintenance Outline

Disassembly

Maintenance Procedure

Reassembly Procedure

Travel Motor

Maintenance Outline

Disassembly

Maintenance Procedure

Reassembly

Performance Checking Test

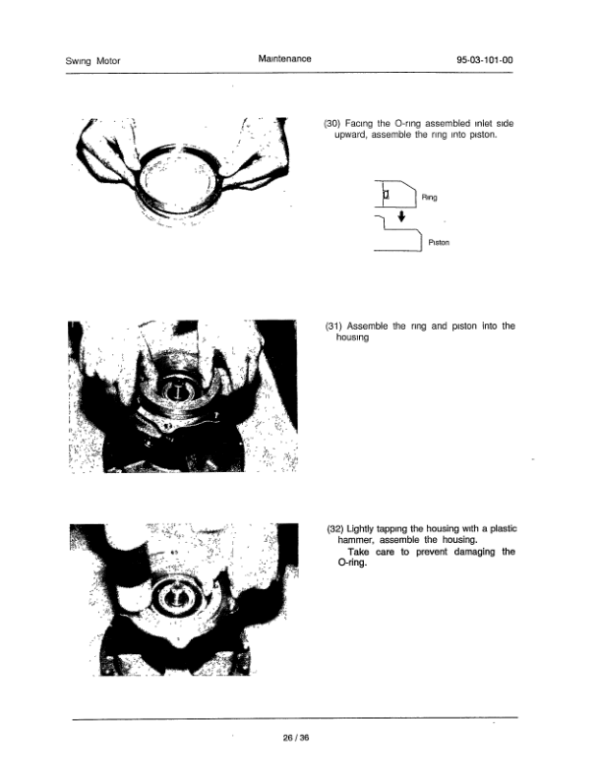

Swing Motor

Maintenance Outline

Cautionary Points for Disassembly and Reassembly

Reassembly Procedure

Maintenance Standards

Control Valve

Maintenance Outline

Disassembly

Cleaning

Inspection

Assembly

Installation

Operation

General Specifications of Control Valve

Troubleshooting

Hydraulic Cylinder

Cylinder Construction

Cautionary

Maintenance

Troubleshooting

Storage Standard

Disassembly and Reassembly

Pilot Valve

Summary

Model Code Numbers

Specifications

Construction

Functions

Actuation

Structural Diagram

Tools and Jigs

Disassembly

Maintenance Standards

Reassembly

Troubleshooting

Rotating Joint

Structural Diagram

Tools and Jigs

Tightening Torques for Bolts

Disassembling Procedure

Reassembling Procedure

Holding Valve

Maintenance Outline

Adjustment of Relief Valve

Disassembling Procedure

Assembling Procedure

Manifold Valve

Maintenance Outline

Adjustment of Relief Valve

Disassembling Procedure

Assembling Procedure

7. Maintenance Standards

Drive Sprocket

Take-Up Roller

Upper Roller

Lower Roller

Track Shoe

Turnable Bearing and Pinion

Attachment Clearance Adjusting Shims

Weight of Components

Tightening Torque Table

Share