1

/

of

4

Uploader

Massey Ferguson 573, 583, 593, 596 Tractor Service Manual Workshop Guide

Massey Ferguson 573, 583, 593, 596 Tractor Service Manual Workshop Guide

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

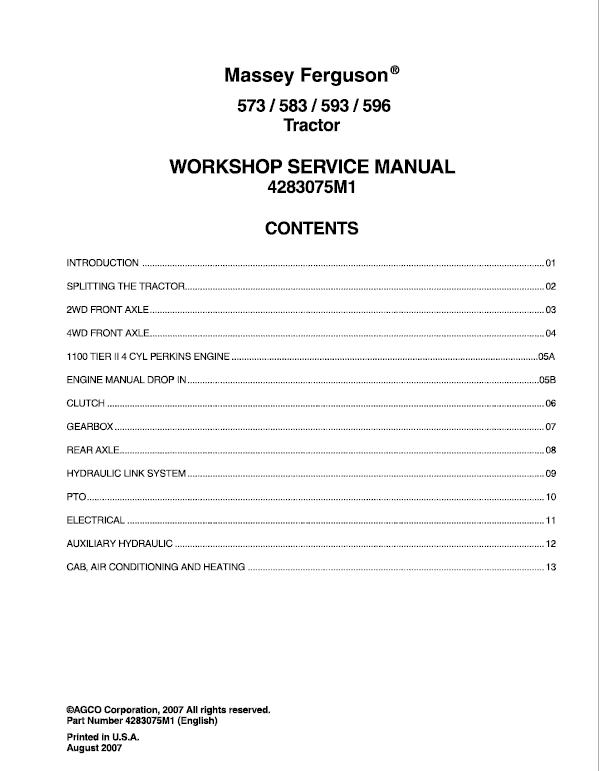

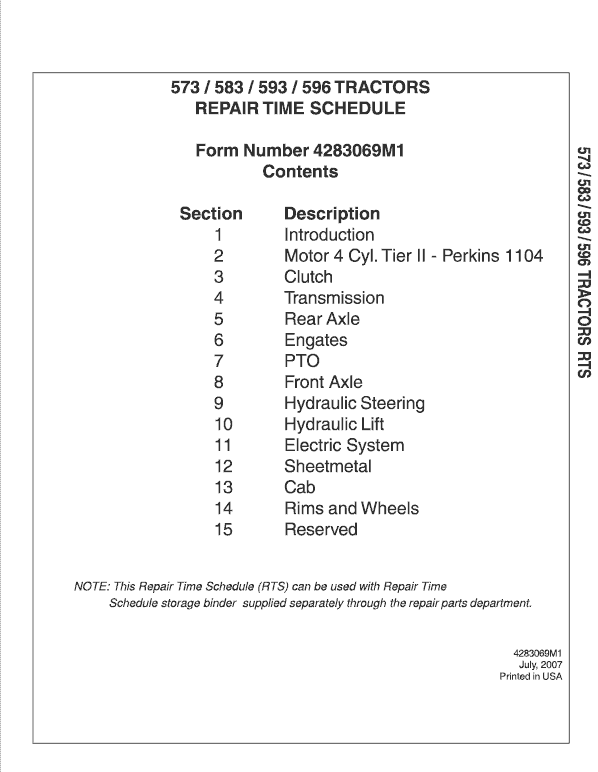

Massey Ferguson 573, 583, 593, 596 Tractors Workshop Manual – 546 Pages

Parts Catalog – 273 Pages

Format: PDF

Language: English

Publication No: 4283075M1

August 2007

Description

Massey Ferguson 573, 583, 593, 596 Tractor Manual

Model:

Massey Ferguson

MF 500 Series Tractor

Format: PDF

Language: English

Publication No: 4283075M1

August 2007

Massey Ferguson 573, 583, 593, 596 Tractors Workshop Manual – 546 Pages

Parts Catalog – 273 Pages

This Manual is composed in Sections:

A …………..Introduction

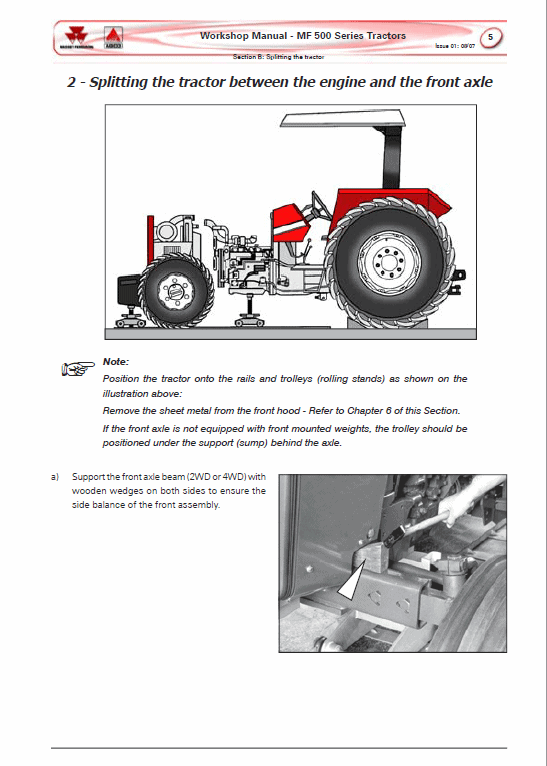

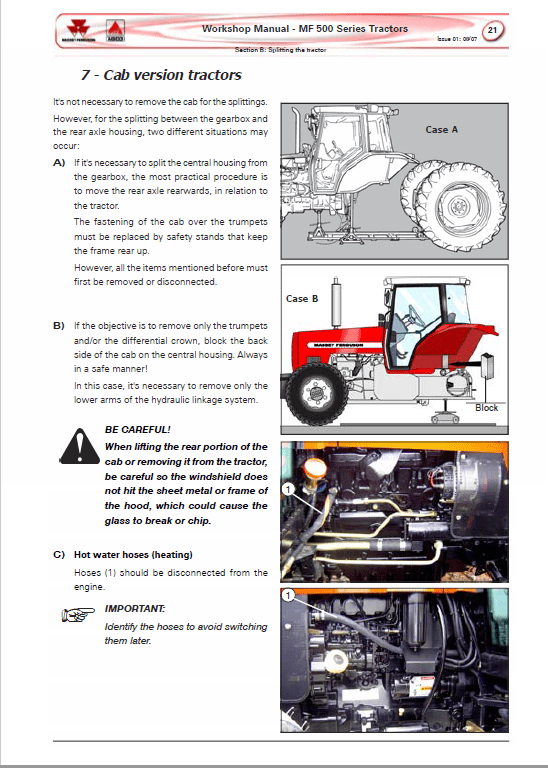

B ………….. Splitting the tractor

C ………….. 2 WD front axle

D………….. 4 WD 20.14 SD and 20.18 CD Carraro front axles

E……………1100 Series – Tier II 4-cylinder Perkins Engines

F ………….. Clutches

G1 …………8 x 2 Speeds Gearbox

G2 …………8 x 8 Synchro Shuttle Gearbox

G3 …………12 x 4 Synchro Gearbox

H…………..Rear axle

I……………Ferguson hydraulic linkage system

J ……………Independent Power Take Off – IPTO

L ………….. Electrical system

M …………. Auxiliary hydraulic systems

N …………..Cab and air conditioner

O …………..Special tools

Clutch troubleshooting

Failure

Cause(s)

Solution

Friction plate binding

– Distortion occurred during

transportation

– Adjust binding, since the friction

plate should not exceed 1.00 mm

Friction plate seized to

pilot-shaft

– Shaft splines were distorted during

refitting

– Hub or splines worn

– The hub rusted on the pilot-shaft

– Eliminate burrs or replace the

friction plate.

– Replace friction plate or shaft or

both

– Clean up and lubricate it lightly.

Friction plate stuck to

flywheel or pressure plate

– Tractor stored for extended period,

without clutch being released.

– Clean the surfaces of the flywheel

and plateau and friction plate,

coating with thin sandpaper.

Friction plate seized to

flywheel or pressure plate

by vacuum

– Rivets without holes or dust in the

holes

– Pierce the hole with a 2 mm

diameter drill boring

– Sandpaper the coating surface to

allow the clutch facing to be

somewhat rough.

Share