1

/

of

4

Uploader

Sumitomo SH75X-6A Hydraulic Excavator Repair Service Manual

Sumitomo SH75X-6A Hydraulic Excavator Repair Service Manual

Regular price

$44.00 USD

Regular price

Sale price

$44.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Sumitomo

Excavator SH75X-6A

Format: PDF

Manual Identification: WLSM0756-00T, WDL0756-2T, WCL0756-0T

English

Mar 2014

Sumitomo SH75X-6A Hydraulic Excavator Repair Service Manual – 1252 Pages

Operators Manual – 272 Pages

Parts Catalog – 528 Pages

Description

Sumitomo SH75X-6A Hydraulic Excavator Repair Service Manual

Sumitomo

Excavator SH75X-6A

Format: PDF

Manual Identification: WLSM0756-00T, WDL0756-2T, WCL0756-0T

English

Mar 2014

Sumitomo SH75X-6A Hydraulic Excavator Repair Service Manual – 1252 Pages

Operators Manual – 272 Pages

Parts Catalog – 528 Pages

Sumitomo SH75X-6A Manual TABLE OF CONTENTS

Safety………………………………………………………………………………………………………………… 3

Safety, general information and standard torque data…………………………………………… 4

General Information…………………………………………………………………………………………. 5

Standard Torque Data For Cap Screws And Nuts………………………………………………. 11

Specifications And Special Torque Settings………………………………………………………. 12

Abbreviation………………………………………………………………………………………………….. 13

Specifications………………………………………………………………………………………………… 20

Main Equipment Table……………………………………………………………………………………. 29

Overall View………………………………………………………………………………………………….. 40

WORK RANGE DIAGRAM……………………………………………………………………………… 44

Main Unit Weight…………………………………………………………………………………………… 48

FLUIDS AND LUBRICANTS……………………………………………………………………………. 64

Circuits and Operation explanation…………………………………………………………………… 69

Main Equipment Structure and Operation Explanation………………………………………… 72

Hydraulic Pump…………………………………………………………………………………………….. 73

Travel Motor………………………………………………………………………………………………….. 82

Swing Motor………………………………………………………………………………………………….. 97

3 Stack Solenoid Valve Operation Explanation………………………………………………… 111

Upper Pilot Valve (remote control valve)…………………………………………………………. 113

Travel Pilot Valve (remote control valve)…………………………………………………………. 119

Blade Pilot Valve (remote control valve)………………………………………………………….. 124

Option Pilot Valve (remote control valve)………………………………………………………… 126

Cushion Valve …………………………………………………………………………………………….. 129

Reverse Prevention Valve…………………………………………………………………………….. 133

2 Stack Solenoid Valve…………………………………………………………………………………. 142

Direction Valve (3-direction) (option)………………………………………………………………. 143

Shut-off Valve……………………………………………………………………………………………… 144

HBCV…………………………………………………………………………………………………………. 145

Engine Summary…………………………………………………………………………………………. 147

Hydraulic Equipment Layout………………………………………………………………………….. 192

Overall View………………………………………………………………………………………………… 193

Port Diagram……………………………………………………………………………………………….. 197

Hydraulic Device………………………………………………………………………………………….. 216

Electrical and Engine Functions and Service Support……………………………………….. 217

Basic Functions…………………………………………………………………………………………… 218

Service Support…………………………………………………………………………………………… 261

Maintenance precautions………………………………………………………………………………. 301

Electrical Equipment Layout Diagram……………………………………………………………… 315

Connection Connector Pin Layout………………………………………………………………….. 342

Sequence Circuit Diagram…………………………………………………………………………….. 345

Removal / Installation and Assembly / Disassembly………………………………………… 361

Pressure Bleeding Operations……………………………………………………………………….. 369

Removal and Installation of Track………………………………………………………………….. 370

Removal and Installation of Shoe Assembly……………………………………………………. 371

Removal and Installation of Shoe Plate…………………………………………………………… 374

Removal and Installation of Roller………………………………………………………………….. 375

Removal and Installation of Upper Roller………………………………………………………… 376

Assembly and Disassembly of Upper Roller…………………………………………………….. 378

Removal and Installation of Lower Roller………………………………………………………… 383

Assembly and Disassembly of Lower Roller…………………………………………………….. 385

Removal and Installation of Drive Sprocket……………………………………………………… 390

Removal and Installation of Take-up Roller……………………………………………………… 391

Assembly and Disassembly of Take-up Roller…………………………………………………. 393

Removal and Installation of Grease Cylinder…………………………………………………… 401

Assembly and Disassembly of Tension Shock Absorber…………………………………… 403

Removal and Installation of Center Joint…………………………………………………………. 406

Assembly and Disassembly of Center Joint…………………………………………………….. 408

Removal and Installation of Travel Motor………………………………………………………… 416

Assembly and Disassembly of Travel Motor…………………………………………………….. 418

Removal and Installation of Swing Unit…………………………………………………………… 464

Assembly and Disassembly of Swing Motor…………………………………………………….. 467

Assembly and Disassembly of Swing Unit……………………………………………………….. 485

Removal and Installation of Hydraulic Pump……………………………………………………. 494

Removal and Installation of Pump Coupling…………………………………………………….. 497

Procedures for Assembly and Disassembly of Hydraulic Pump Main Unit……………. 498

Pump Main Unit Maintenance Standards………………………………………………………… 504

Removal and Installation of Control Valve……………………………………………………….. 514

Procedures for Assembly and Disassembly of Control Valve……………………………… 521

Removal and Installation of Engine Assembly………………………………………………….. 551

Removal and Installation of Fuel Cooler, Engine Intercooler, Radiator, and Oil

Cooler………………………………………………………………………………………………………… 556

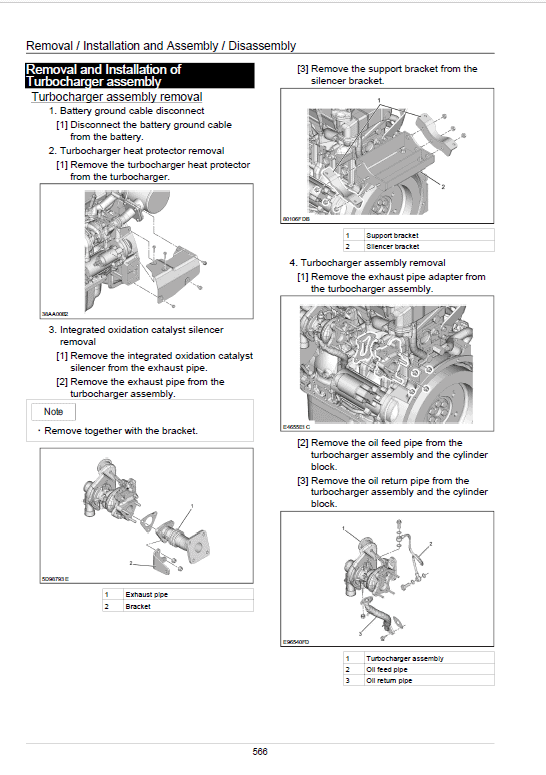

Removal and Installation of Turbocharger assembly…………………………………………. 566

Removal and Installation of EGR Valve…………………………………………………………… 570

Removal and Installation of Engine Hood………………………………………………………… 572

Removal and Installation of Muffler………………………………………………………………… 573

Removal and Installation of Cylinder Head Cover…………………………………………….. 574

Removal and Installation of Idle gear……………………………………………………………… 600

Removal and Installation of Cylinder Block……………………………………………………… 608

Lubrication System………………………………………………………………………………………. 640

Cooling System……………………………………………………………………………………………. 650

Disassembly, Removal and Installation of Crankshaft……………………………………….. 657

Disassembly, Removal and Installation of Piston……………………………………………… 688

Removal and Installation of Camshaft…………………………………………………………….. 711

Removal and Installation of Flywheel……………………………………………………………… 732

Removal and Installation of Crankshaft front oil seal…………………………………………. 735

Removal and Installation of Crankshaft rear oil seal…………………………………………. 739

Removal and Installation of Rocker arm shaft………………………………………………….. 745

Removal and Installation of Valve spring…………………………………………………………. 752

Removal and Installation of Valve stem oil seal……………………………………………….. 769

Removal and Installation of Intake chamber…………………………………………………….. 787

Removal and Installation of Integrated oxidation catalyst silencer………………………. 791

Removal and Installation of Generator……………………………………………………………. 793

Removal and Installation of Exhaust Manifold………………………………………………….. 799

Removal and Installation of Fuel Supply Pump………………………………………………… 805

Removal and Installation of Common Rail Assembly………………………………………… 810

Removal and Installation of Injector………………………………………………………………… 812

Removal and Installation of Starter Motor……………………………………………………….. 817

Removal and Installation of Alternator…………………………………………………………….. 818

Preheating System………………………………………………………………………………………. 820

Introduction to the trouble diagnosis……………………………………………………………….. 825

Removal and Installation of Fuel Tank……………………………………………………………. 849

Removal and Installation of Hydraulic Tank…………………………………………………….. 852

Removal and Installation of Pilot Blocs……………………………………………………………. 857

Removal and Installation of Travel Remote Control Valve…………………………………. 858

Procedures for Assembly and Disassembly of Travel Remote Control Valve……….. 861

Removal and Installation of Option Remote Control Valve…………………………………. 874

Assembly and Disassembly Procedures of Option Remote Control Valve……………. 877

Removal and Installation of Operation Remote Control Valve……………………………. 885

Procedures for Assembly and Disassembly of Operation Remote Control Valve….. 893

Removal and Installation of Blade Remote Control Valve………………………………….. 904

Assembly and Disassembly Procedures…………………………………………………………. 907

Removal and Installation of 3 Stack Solenoid………………………………………………….. 915

Removal and Installation of Cushion Valve……………………………………………………… 917

Assembly and Disassembly of Cushion Valve………………………………………………….. 919

Removal and Installation of Operator's Seat……………………………………………………. 920

Removal/installation of the KAB Seat……………………………………………………………… 921

Removal and Installation of Cab Assembly……………………………………………………… 922

Removal and Installation of Wiper………………………………………………………………….. 926

Removal and Installation of Wiper Controller…………………………………………………… 927

Removal and Installation of Wiper Motor…………………………………………………………. 928

Removal and Installation of ECM…………………………………………………………………… 930

Removal and Installation of Computer A…………………………………………………………. 931

Removal and Installation of Computer B…………………………………………………………. 932

Removal and Installation of Monitor……………………………………………………………….. 933

Removal and Installation of Cab Front Glass…………………………………………………… 935

Window Lock Adjustment Procedures…………………………………………………………….. 937

Tightening torque…………………………………………………………………………………………. 939

Removal and Installation of Counterweight……………………………………………………… 940

Removal and Installation of Bucket………………………………………………………………… 944

Removal and Installation of Bucket Link………………………………………………………….. 946

Removal and Installation of Arm…………………………………………………………………….. 948

Removal and Installation of Boom………………………………………………………………….. 950

Removal and Installation of Blade………………………………………………………………….. 954

Removal and Installation of Bucket Cylinder……………………………………………………. 956

Removal and Installation of Arm Cylinder………………………………………………………… 959

Removal and Installation of Boom Cylinder……………………………………………………… 963

Removal and Installation of Blade Cylinder……………………………………………………… 967

Procedures for Operation/Assembly and Disassembly of Hydraulic Cylinder

(made by KYB)……………………………………………………………………………………………. 971

Removal and Installation of HBCV……………………………………………………………….. 1002

List of special tools…………………………………………………………………………………….. 1004

Maintenance standards and Measurement procedures………………………………….. 1023

Pressure Measurement and Adjustment Procedures………………………………………. 1024

Hydraulic Pump Flow Measurement Procedures……………………………………………. 1037

Drain Volume Measurement Procedures……………………………………………………….. 1041

Air Bleed Procedure……………………………………………………………………………………. 1044

Maintenance Standards………………………………………………………………………………. 1047

Bolt Size and Torque Table…………………………………………………………………………. 1067

New Machine Performance Judgment Table………………………………………………….. 1072

Air Conditioning…………………………………………………………………………………………… 1083

Air Conditioner Overall Diagram…………………………………………………………………… 1084

Assembly and Disassembly of Unit………………………………………………………………. 1124

Removal and Installation of Compressor……………………………………………………….. 1129

Removal and Installation of Condenser…………………………………………………………. 1130

Removal and Installation of Receiver Dryer…………………………………………………… 1132

Work Precautions………………………………………………………………………………………. 1134

Troubleshooting…………………………………………………………………………………………… 1143

Engine-side Diagnostic Trouble Code List……………………………………………………… 1146

Main Unit-side Diagnostic Trouble Code List………………………………………………….. 1148

Diagnostic Trouble Code Display on the Front Screen…………………………………….. 1149

Engine-side Trouble……………………………………………………………………………………. 1150

Main Unit-side Trouble………………………………………………………………………………… 1197

Symptom…………………………………………………………………………………………………… 1229

Data Reference Values……………………………………………………………………………….. 1241

The Sumitomo Manual Preface

The purpose of this Sumitomo Excavator manual is to assist dealers and repair serviceman in efficient repair and maintenance of their machinery. Carrying out the procedures as detailed, together with the use of any special tools needed.

Using the Sumitomo SH75X-6A Manual

To make information easier to find, there is an index at the beginning of each section listing the various parts in that section. At the beginning of each part there is a table of contents which should also be used as a guide to locate information.

To assist with locating information, each section of the manual is preceded by a contents page listing the repair operations, Each instruction within an operating has a sequence number. To complete the operation in the minimum time is possible follow the manual guideline and repair instructions.

When parts have to be replaced in either the SH75X-6A Hydraulic Excavator , it is essential that only genuine Sumitomo parts should be used. Special attention should be paid to the following points concerning repairs and the fitting of replacement parts and accessories.

Indexing

For convenience the manual is divided into section and parts, each page bearing a section and part number. The sections are subdivided into numbered operation. This simplifies cross referencing and enable the subject to be found easily.

Share