1

/

of

4

Uploader

Takeuchi TW50 Wheel Loader Service Manual Workshop Guide

Takeuchi TW50 Wheel Loader Service Manual Workshop Guide

Regular price

$33.50 USD

Regular price

Sale price

$33.50 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Takeuchi TW50 Service Repair Manual – 242 Pages

Takeuchi TW50 Operators Manual – 84 Pages

Parts Manual – 115 Pages

Engine Manual for HP818485U -132 Pages

Description

Takeuchi TW50 Wheel Loader Service Manual

Type:

Loader

TW50

Format: PDF

Language of the Manuals: English

Takeuchi TW50 Service Manual – 242 Pages

Takeuchi TW50 Operators Manual – 84 Pages

Parts Manual – 115 Pages

Engine Manual for HP818485U -132 Pages

For All applicable S/N

The manual describes operation, service, repair and maintenance of the Loader, as well as safety instructions that should be follow.

The Takeuchi TW50 manual is intended for persons who engage in maintenance operations, and explains procedures for disassembly and reassembly of the machine, check and maintenance procedures, maintenance reference values, troubleshooting and outline specifications, etc. Please use this Takeuchi manual for Loader TW50 as a reference in service activities to improve maintenance techniques.

Please note that the contents and diagrams included in this manual may not match your machine exactly.

Items or diagram which manual contains are subject to change without notice due to design modifications, etc. Always store the Takeuchi Loader manual near at hand preferably on the machine itself. When transferring ownership of this machine, be sure to provide the owner manual to the next owner.

Table of Content of TW50 Instructions Manual:

I . GENERAL

II . SPECIFICATIONS

III. MACHINE CONFIGURATION

IV. HYDRAULIC UNITS

V . TROUBLESHOOTING

VI. ENGINE

Before operating, perform the prescribe inspections and make repairs immediately should any irregularities be found. If a failure that causes loss of control such as steering, service brakes or engine occurs, stop the machine motion as quickly as possible, follow the shutdown procedure, and keep machine securely park until the problem is fixed.

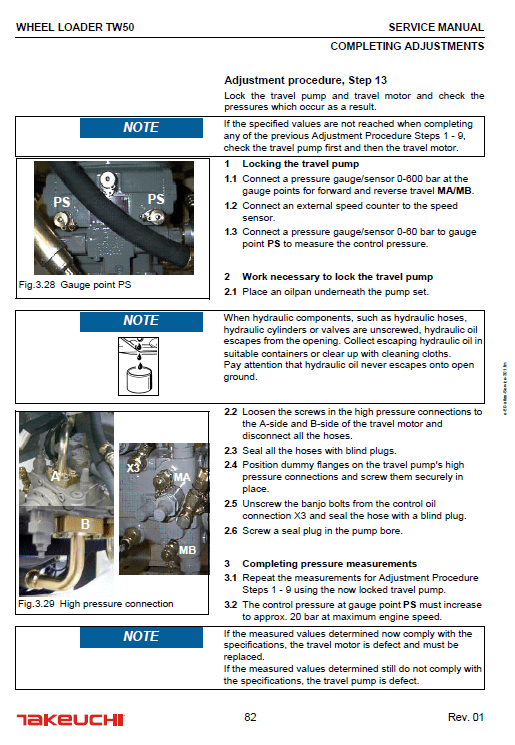

Extract from the Service Manual:

Replacing the hoisting gear components

Unscrew any locking screws (1.1) still in the bearing bolts.

• Use a hydraulic press to force out any bearing bolts (1) remaining.

• Use a crane or hoisting system to support heavy components.

• Clean the bearing bolts (1) pressed out.

• Clean the bearing bushes.

• Check the bearing bushes (2) for scoring and signs of damage.

Replacing the bearing bushes

• If the bearing bushes are inserted with retaining rings, they must be removed.

• Press the bearing bushes (2) to be replaced out of the bearing.

• Clean the bearing and greasing holes.

• Press the new bearing bushes (2) in the corresponding bearing.

• Pay attention to the correct position of the greasing holes.

• If available, insert the retaining rings again.

• Grease the bearing bushes (2).

• Install the component back in the hoisting gear and press the bearing bolts (1) in.

• When pressing them in, pay attention to the correct position of the bearing bolt (1).

• Screw in new locking screws (1.1).

Share