1

/

of

4

Uploader

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

Regular price

$31.00 USD

Regular price

Sale price

$31.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Format: PDF

Language: English

4,500 lb. Powered Pallet Walkie Model: 6HBW23

Serial Number 22,000 and up

TOYOTA 6HBW23 Forklift Repair Manual – 151 Pages

Description

Toyota 6HBW23 Powered Pallet Walkie Service Repair Manual

Format: PDF

Language: English

4,500 lb. Powered Pallet Walkie Model: 6HBW23

Serial Number 22,000 and up

TOYOTA 6HBW23 Forklift Repair Manual – 151 Pages

This manual covers the inspection, adjustment and repair procedures mainly for the overhaul of the engine, chassis and material handling system of the TOYOTA ELECTRIC POWERED FORKLIFT 7FBEU15 to 20 series and 7FBEHU18.

This repair manual contains the latest information available. Please under-stand that disagreement can take place between the descriptions in the manual and actual vehicles due to change in design and specifications. Any change or modifications thereafter will be informed by Toyota Industrial Equipment Parts & Service News.

For the service procedures of the mounted engine, read the repair manuals listed below as reference together with this manual.

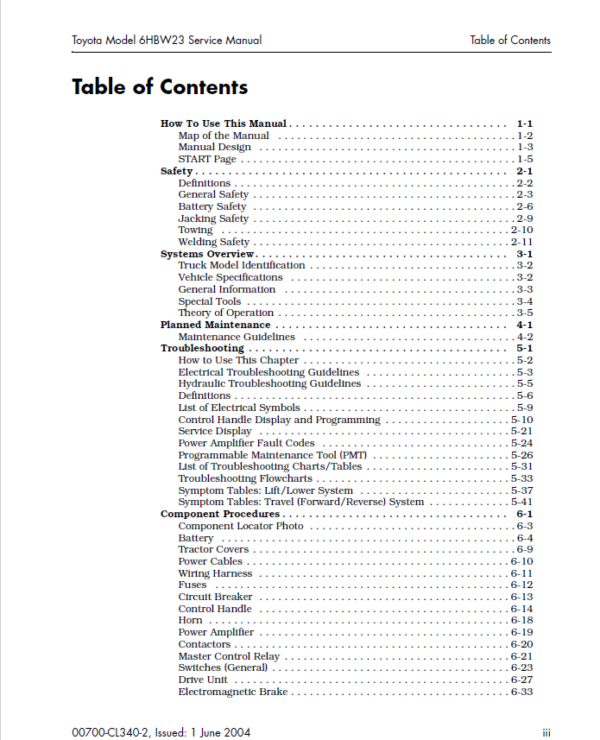

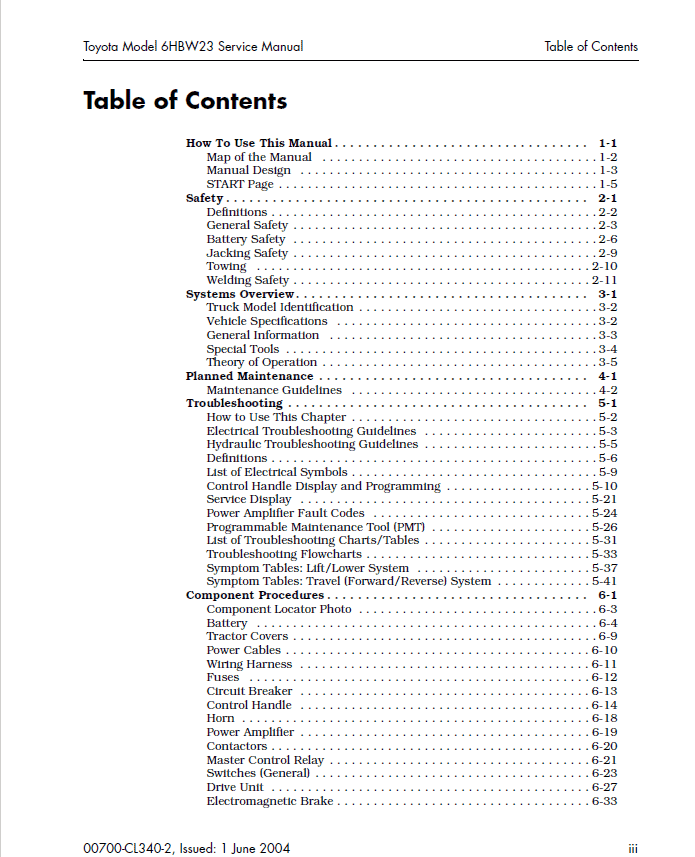

Table of content of the Repair Service Manual

HOW TO USE THE MANUAL

SAFETY

SYSTEM OVERVIEW

PLANNED MAINTENANCE

TROUBLESHOOTING

ELECTRICAL CODES AND TESTS

COMPONENT PROCEDURES

THEORY OF OPERATION

APPENDIX

INDEX

Truck Starting

To start the truck, the battery is plugged in, the Master Control ON/OFF switch is in the ON position, the PIN-key code is entered in the

keypad, and the green ON (|) key pressed (or optional key switch is ON). See "Service Display" on page 5-21.

Lift/Lower

The lift/lower system consists of an electrically operated hydraulic pump assembly and related components.

The hydraulic pump assembly consists of a positive displacement rotary gear pump with reservoir mounted to an adapter. A DC electric

motor is mounted to the opposite side of the pump adapter. An adjustable relief valve, check valve, and a solenoid operated lowering valve

are installed within the adapter.

With the forks elevated, the normally closed solenoid valve and the check valve prevent hydraulic fluid from returning to the reservoir.

Share