1

/

of

4

Uploader

Toyota 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55 Forklift Repair Manual

Toyota 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55 Forklift Repair Manual

Regular price

$36.00 USD

Regular price

Sale price

$36.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Format: PDF

Language: English

Model Covered: 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55

TOYOTA 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55 Forklift Repair Manual – 918 Pages

Supplement Manual – 91 Pages

Description

Toyota 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55 Forklift Repair Manual

Format: PDF

Language: English

Model Covered: 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55

TOYOTA 7FBCU30, 7FBCU32, 7FBCU35, 7FBCU45, 7FBCU55 Forklift Repair Manual – 918 Pages

Supplement Manual – 91 Pages

This manual covers the inspection, adjustment and repair procedures mainly for the overhaul of the engine, chassis and material handling system of the TOYOTA ELECTRIC POWERED FORKLIFT 7FBCU15 – 55 series.

This repair manual contains the latest information available. Please under-stand that disagreement can take place between the descriptions in the manual and actual vehicles due to change in design and specifications. Any change or modifications thereafter will be informed by Toyota Industrial Equipment Parts & Service News.

For the service procedures of the mounted engine, read the repair manuals listed below as reference together with this manual.

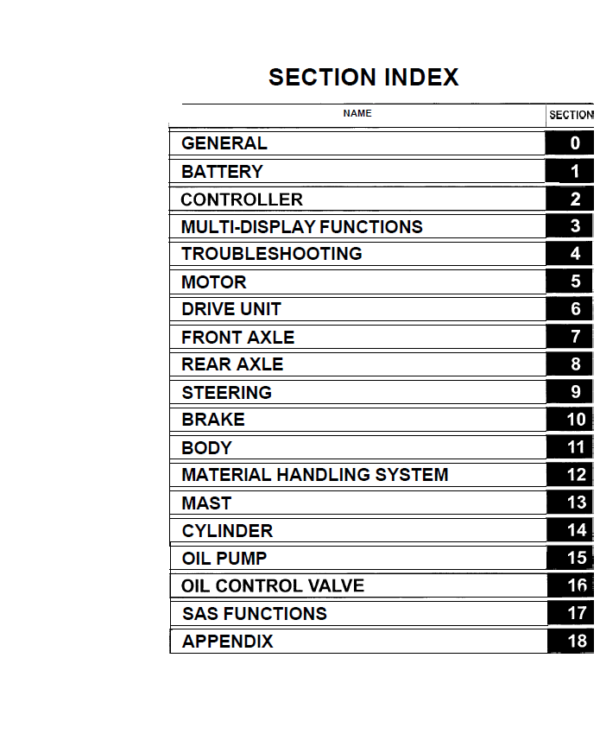

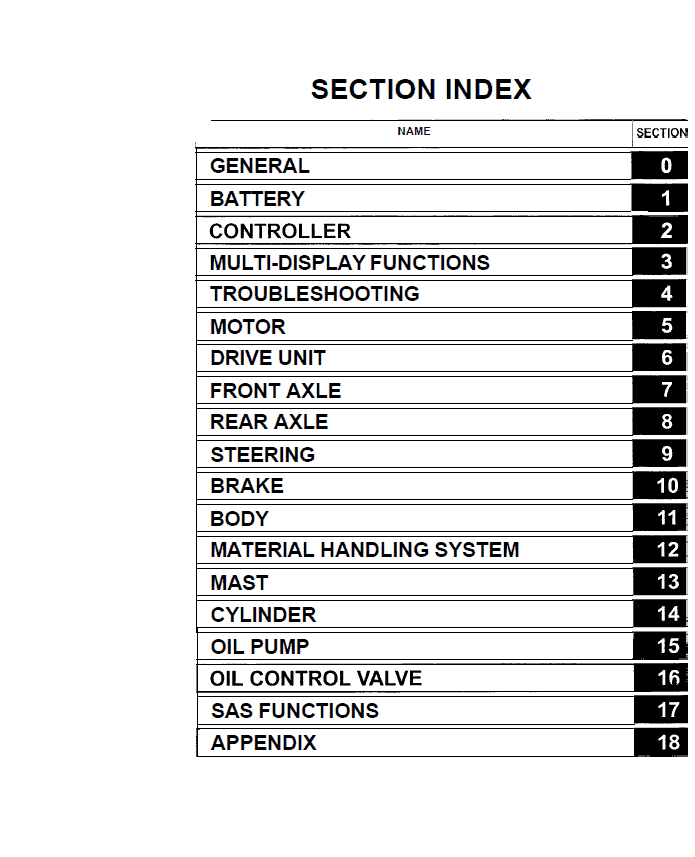

Table of content of the Repair Service Manual

GENERAL

BATTERY

MULTI-DISPLAY FUNCTIONS

TROUBLESHOOTING

MOTOR

DRIVE UNIT

FRONT AXLE

REAR AXLE

STEERING

BRAKE

BODY

MATERIAL HANDLING SYSTEM

MAST

CYLINDER

OIL PUMP

SAS FUNCTIONS

APPENDIX

Control specification

1. Travel OPS (Not change from the present specification)

When the controller detects the seat switch turned off for two seconds, the drive motor control is stopped.

Travel OPS is released by returning the direction lever and accelerator pedal to the neutral position and turning on the seat switch.

2. Material handling OPS

7FBCU 15 ~ 32, 7FBCU 35 ~ 55 (With deadman brake spec. (OPT)):

When the OPS controller detects seat switch OFF for 2 seconds, the lift lock valve, tilt control valve and backward tilting lock valve are controlled to disable fork lowering and forward tilting operations. Backward tilting, fork lifting and attachment operations are disabled by stopping the pump motor. The disabled material handling operations are released upon lapse of 1 second after seat switch ON.

Caution:

• Backward tilting: If the material handling lever is operated while the OPS is functioning, the mast may move because of its own weight when it is in a backward tilted position.

• Attachment: If the material handling lever is operated while the OPS is functioning, the attachment may move because of its own weight.

7FBCU 35 ~ 55 (Without deadman brake):

When the OPS controller detects seat switch OFF for 2 seconds, the lift lock valve, tilt control valve and backward tilting lock valve are controlled to disable fork lowering and forward/backward tilting operations. Fork lifting and attachment operations are disabled by interrupting the hydraulic oil supply by means of the unload valve. Fork lowering operation is stopped by stopping the pump motor. The material handling operations disabled by the OPS are released upon lapse of 1 second after seat switch ON.

Caution:

• Attachment: If the material handling lever is operated while the OPS is functioning, the attachment may move because of its own weight.

• Fork lifting and attachment: If the material handling lever is operated with the brake pedal depressed while the OPS is functioning, pump motor runs at a low speed to ensure brake power assist, causing fork lifting and attachment operation at creeping speeds.

Share