1

/

of

4

Uploader

Toyota 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20 Forklift Repair Manual

Toyota 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20 Forklift Repair Manual

Regular price

$34.00 USD

Regular price

Sale price

$34.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Format: PDF

Language: English

Model Covered: 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20

TOYOTA 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20 Forklift Repair Manual – 513 Pages

Description

Toyota 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20 Forklift Repair Manual

Format: PDF

Language: English

Model Covered: 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20

TOYOTA 7FBE10, 7FBE13, 7FBE15, 7FBE18, 7FBE20 Forklift Repair Manual – 513 Pages

This manual covers the inspection, adjustment and repair procedures mainly for the overhaul of the engine, chassis and material handling system of the TOYOTA ELECTRIC POWERED FORKLIFT 7FBE10 to 20 series.

This repair manual contains the latest information available. Please under-stand that disagreement can take place between the descriptions in the manual and actual vehicles due to change in design and specifications. Any change or modifications thereafter will be informed by Toyota Industrial Equipment Parts & Service News.

For the service procedures of the mounted engine, read the repair manuals listed below as reference together with this manual.

Table of content of the Repair Service Manual

GENERAL

BATTERY

CHARGER (OPT)

CONTROLLER

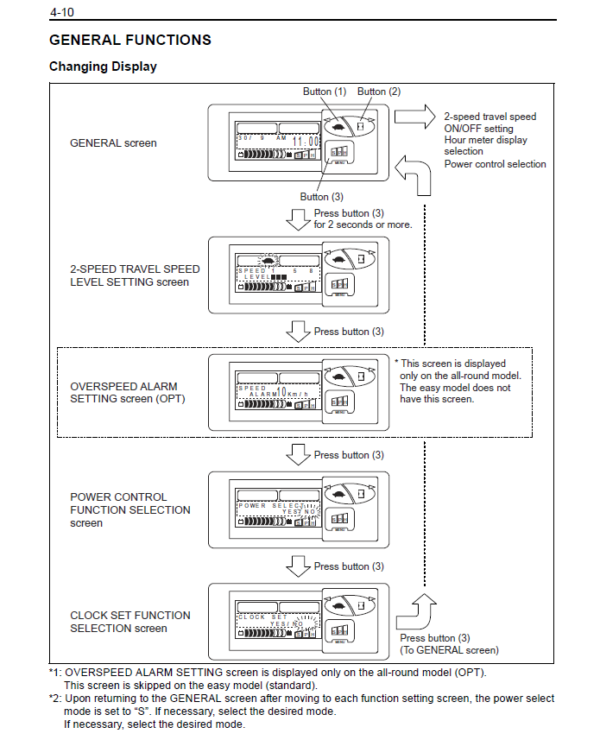

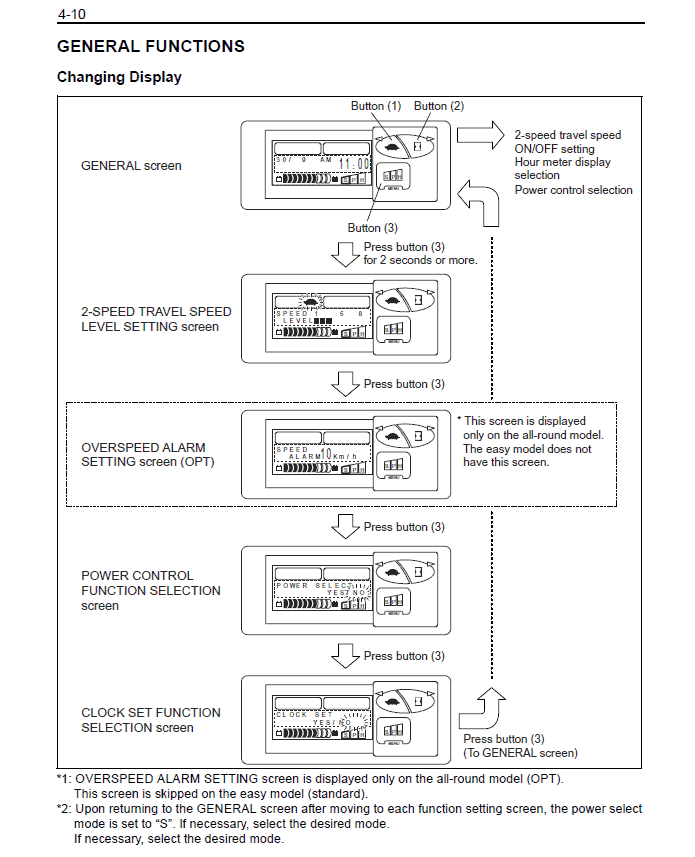

MULTI-DISPLAY FUNCTIONS

TROUBLESHOOTING

MOTOR

DRIVE UNIT & FRONT AXLE

REAR AXLE

STEERING

BRAKE

BODY & FRAME

MATERIAL HANDLING SYSTEM

MAST

CYLINDER

OIL PUMP

OIL CONTROL VALVE

SAS FUNCTIONS (OPT)

APPENDIX

GENERAL INSTRUCTIONS

1. Skillful operation

(1) Prepare the tools, necessary measuring instruments (circuit tester, megohmmeter, oil pressure gauge, etc.) and SSTs before starting operation.

(2) Check the cable color and wiring state before disconnecting any wiring.

(3) When overhauling functional parts, complicated sections or related mechanisms, arrange the parts neatly to prevent confusion.

(4) When disassembling and inspecting a precision part such as the control valve, use clean tools and operate in a clean location.

(5) Follow the specified procedures for disassembly, inspection and reassembly.

(6) Always replace gaskets, packing, O-rings, self-locking nuts and cotter pins with new ones each time they are disassembled.

(7) Use genuine Toyota parts for replacement.

(8) Use specified bolts and nuts and observe the specified tightening torque when reassembling.

(Tighten to the medium value of the specified tightening torque range.) If no tightening torque is specified, use the value given in the "standard tightening torque table".

Share