1

/

of

4

Uploader

Toyota 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32 Forklift Repair Manual Workshop Guide

Toyota 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32 Forklift Repair Manual Workshop Guide

Regular price

$45.00 USD

Regular price

Sale price

$45.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Format: PDF

Language: English

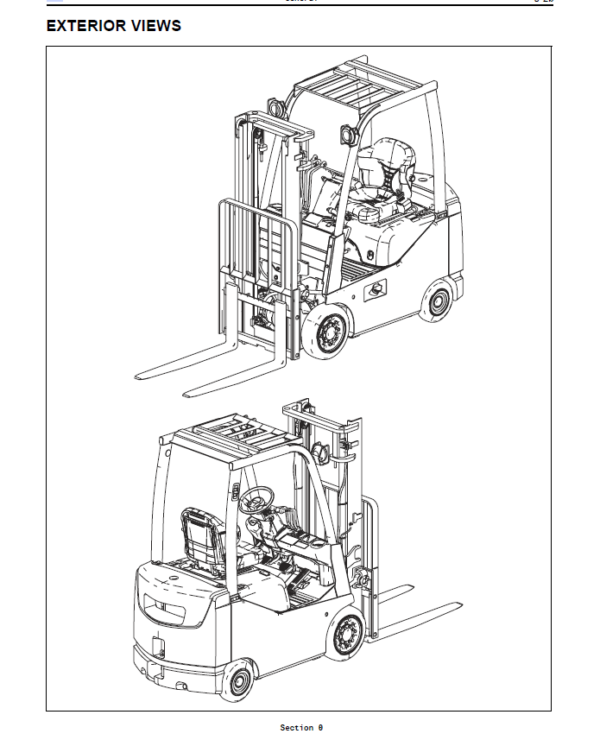

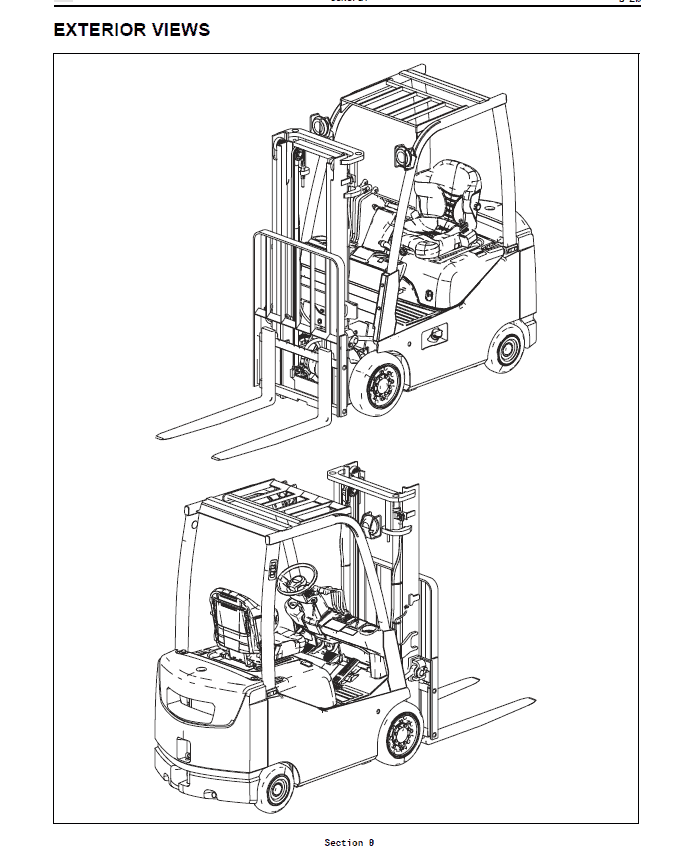

Model Covered: 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32

TOYOTA 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32 Forklift Repair Manual – 1389 Pages & 1867 Pages

Supplement Manual (above models as of April 2010) – 227 Pages

Parts Catalog – 166 Pages

4Y model Engine Manual – 250 Pages

4Y-E Engine Manual – 104 Pages

1DZ-II Engine Manual – 196 Pages

Description

TOYOTA 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32 Forklift Repair Manual

Format: PDF

Language: English

Model Covered: 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32

TOYOTA 8FDU15, 8FDU18, 8FDU20, 8FDU25, 8FDU30, 8FDU32 Forklift Repair Manual – 1389 Pages & 1867 Pages

Supplement Manual (above models as of April 2010) – 227 Pages

Parts Catalog – 166 Pages

4Y model Engine Manual – 250 Pages

4Y-E Engine Manual – 104 Pages

1DZ-II Engine Manual – 196 Pages

This manual covers the service procedures of the TOYOTA FORKLIFT 8FDU15 – 32 series. Please use this manual for providing quick, correct servicing of the corresponding forklift model;.

This manual deals with the models realease for this forklift even those after April 2010. Please under-stand that disagreement can take place between the descriptions in the manual and actual vehicles due to change in design and specifications. Any change or modifications thereafter will be informed by Toyota Industrial Equipment Parts & Service News.

For the service procedures of the mounted engine, read the repair manuals listed below as reference together with this manual.

Table of content of the Repair Service Manual

GENERAL

ENGINE – CHASSIS

4Y-E REPAIR

1DZ-II REPAIR

4Y-E LPG DEVICE REPAIR

TRANSMISSION (Pn1•2•3 / Cu2•3)

TRANSMISSION (Cu1 Ton Series)

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE

REAR AXLE

STEERING

BRAKE

BODY

MATERIAL HANDLING SYSTEM

MAST

CYLINDER

OIL PUMP

OIL CONTROL VALVE

MINI LEVER – JOYSTICK

SAS / OPS

SSTLIST – SERVICE STANDARDS LIST

MULTIFUNCTION DISPLAY DX (OPTIONAL)

ELECTRICAL SYSTEM TROUBLESHOOTING [except Cu1]

ELECTRICAL SYSTEM TROUBLESHOOTING [Cu1 ton series]

WIRING DIAGRAM

SERVICE INFORMATION BULLETINS

OPERATIONAL TIPS

1. Safe operation

(1) After jacking up, always support with wooden blocks or rigid stands.

(2) When hoisting the vehicle or its heavy component, use wire rope(s) with a sufficient reserve in load

capacity.

(3) Always disconnect the battery terminal before the inspection or servicing of electrical parts.

Share