1

/

of

4

Uploader

Volvo A20C Articulated Dump Truck Repair Service Manual Workshop Guide

Volvo A20C Articulated Dump Truck Repair Service Manual Workshop Guide

Regular price

$47.00 USD

Regular price

Sale price

$47.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Repair Service Manual:

301 Pages

Specifications:

Brand:

Volvo

Model:

A20 6×4 BM

Type:

Articulated Dump Truck

Manuals:

Repair Service Manual

Publication Numbers:

Ref. No 252954 3588

Language:

English

Format:

PDF

Description

Table of Content A20C Service Information

GENERAL

DESCRIPTION, COMPLETE MACHINE

General

SPECIFICATIONS

Volvo standard tightening torques

STANDARD TIME

TOOL

Below are drawings of the E-tools that can be made in your own workshop.

STANDARD PARTS, SERVICE

LUBRICANT; FUEL; OTHER FLUID

Brake system, changing brake fluid

SERVICE

General, common info about 171 – 179

Electric welding

Emergency measures

ENGINE WITH MOUNTING AND EQUIPMENT

ENGINE

General, common info about 211 – 218

Compression check, engine at operating temperature

Specifications, general

Cylinder head

Specifications, tightening torques

Cylinder block with crankcase ventilation

Valve mechanism

Valves, adjusting

Engine transmission; camshaft

Crank shaft; connecting rod; vibration damper; fly wheel

Oil sump, dipstick incl.

Engine mounting

LUBRICATING SYSTEM

General, common info about 221 – 224

Oil pump; line

Lubrication oil pressure, checking

FUEL SYSTEM

General (common info about 233 – 238)

Low emission engines

Fuel pump; filter; strainer

Fuel feed pump, checking feed pressure

Fuel tank; fuel filling pump

Specifications, capacities

Injection pump; regulator; pump companion

Fuel injection pump, changing incl. setting injection timing

Idle speed, checking and adjusting

Injection angle TDC, checking and adjusting

Slow and fast idle speed, checking and adjusting with service display unit

Stall speed, checking with service display unit

Injector; delivery pipe

Injectors, changing all

Control system; control unit (for ex. injection timming adjuster)

Automatic timing adjuster, checking

Automatic timing adjuster (alpha adjuster)

INLET SYSTEM; EXHAUST SYSTEM

Inlet manifold; exhaust manifold

Turbo charger

Air cleaner with connections; air pre-heater

COOLING SYSTEM

General, common info about 261 – 269

Radiator, mounting and connections included

Coolant, changing

Fan; fan shroud; fan coupling

Hydraulic motor for fan or hydraulic pump, checking internal leakage

Radiator fan drive, checking function of motor

Radiator fan drive, general description

ENGINE CONTROL

Revs control, foot operated

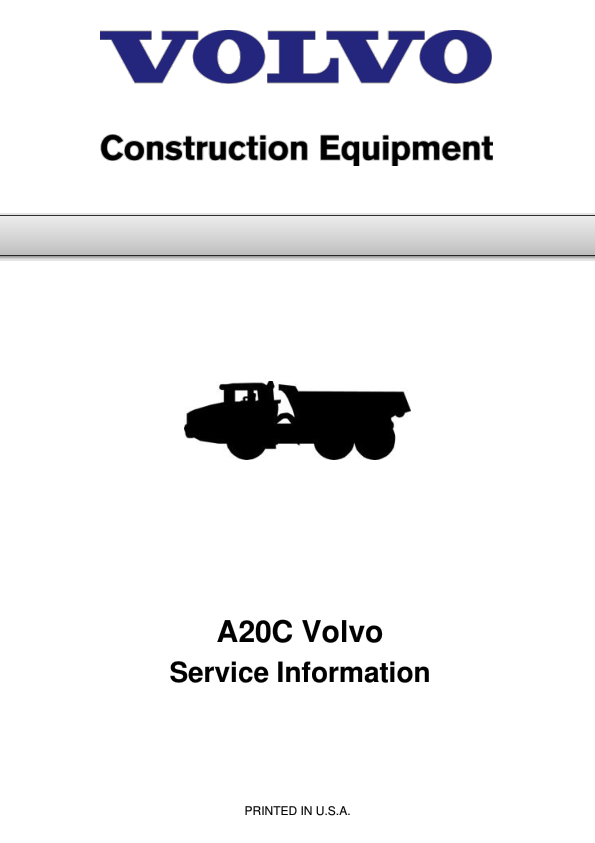

Throttle pedal, anti-throttle cylinder, adjusting

ELEC. SYSTEM; WARNING SYSTEM; INFORMATION SYSTEM; INSTRUMENTS

Comprehensive info, electrical system

BATTERY; ENERGY STORAGE SYSTEM; MOUNTING PARTS

Battery

ALTERNATOR; CHARGING; ELECTRIC MOTOR; ELECTRIC DRIVES

Alternator inclusive drive

Charging; converter

STARTING SYSTEM

Starter motor inclusive solenoid

LIGHTING

General, common info about 351 – 356

Lighting, front, including parking light and day running light

CABLE; FUSE; RELAY

General, common info about 371 – 379

Cable; battery disconnector

Electrical distribution box; fuse box; junction box

INSTRUMENT; SENSOR; WARNING AND INFORMATION SYSTEM

General, common info about 383 – 387

Speedometer; trip meter; hour counter

Sender, monitoring system

Warning/information unit, display unit

POWER TRANSMISSION

General, common info about 410 – 436

CLUTCH; TORQUE CONVERTER

Hydrodynamic coupling, torque converter

TRANSMISSION, HYDRAULIC CONTROL

Hydraulic diagram, transmission without retarder

Transmission functions, checking instructions for connector X1/A1

Transmission PT1051 ހ" cut-away drawing

Transmission PT1052, general description

Transmission, general troubleshooting

Troubleshooting outside the control unit in connector X1/A1

Wiring diagram, transmission electronics, circuit 37a-I

Transmission, hydraulic control

Diagnosis using error codes on service display unit

Gearshift selector, checking

Hydraulic transmission, checking oil pressure

Inductive sensor for output shaft, changing

Inductive sensor for turbine speed, changing

Oil cooler, changing

Seal for rear output shaft, changing

Solenoids, checking resistance

Transmission, removing and mounting (engine removed from machine)

Transmission, removing and mounting (together with engine)

GEARBOX,

Distributing gearbox

Dropbox FL 650 D, general description

Dropbox, changing seal for rear output shaft

Dropbox, changing seal for front output shaft

Longitudinal differential lock, adjusting engagement

PROPELLER SHAFT

General, common info about 451 – 453

Propeller shaft, complete

Intermediate propeller shaft and/or bearing, changing (in frame joint)

Propeller shaft between dropbox and frame joint, changing

Propeller shaft between transmission and dropbox, changing

Propeller shaft for rear bogie axle, changing

Propeller shaft, front output shaft on dropbox, changing

Propeller shaft for front bogie axle, changing

FRONT AXLE; REAR AXLE

General, common info about 461 – 468

Dog clutch 66, checking and adjusting

Final drive 66 output shaft, changing seals and bearings

Front axle

Front axle assembly, removing

Differential lock, with control

Transverse differential lock, adjusting engagement (per axle)

POWER TAKE OFF

Power take off

Power take off, between engine and gearbox (ART)

Flywheel housing (rear engine transmission) and power take-off

Power take-off in flywheel housing, reconditioning

Power take-off in flywheel housing, changing

BRAKE

Comprehensive info about brakes

WHEEL BRAKE

General, common info about 511 – 519

Brake pads for service brake, checking

Specifications, weights

Front wheel brake, dry brake

Brake caliper, changing (per caliper)

Brake disc, changing

HYDRAULIC BRAKE SYSTEM

General, common info about 520 – 522

Brake system, bleeding

Brake valve

PARKING BRAKE

General, common info about 551 – 554

Parking brake caliper removed, reconditioning

Parking brake valve ހ" hand-operated lever

Parking brake valve, reconditioning

Parking brake, changing brake caliper

Parking brake, changing brake disc

Parking brake, changing brake pads

Spring brake cylinder removed, reconditioning

Propeller shaft brake

COMPRESSED-AIR BRAKE

General, common info about 561 – 565

Four-way pressure retaining valve, reconditioning (removed)

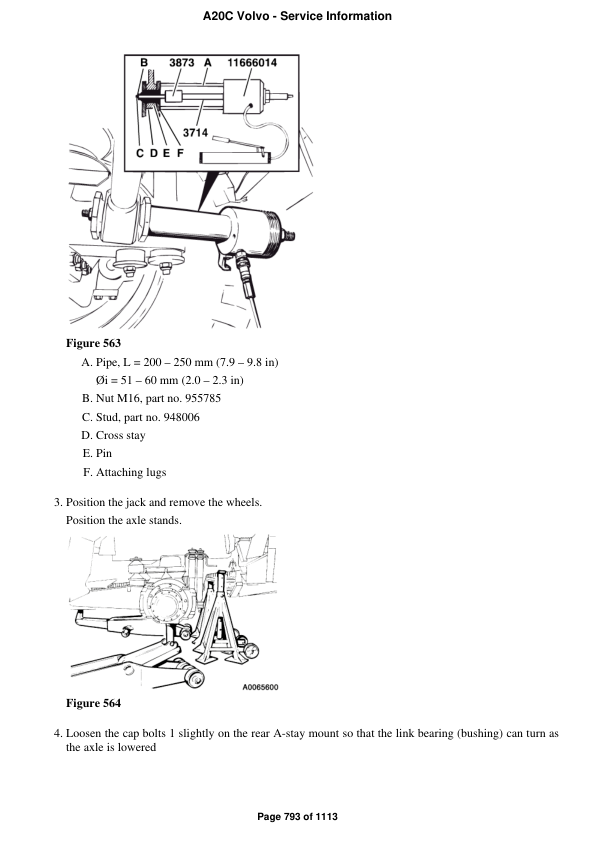

Compressor; regulator; anti-freez unit

Cut-out and cut-in pressures, checking and adjusting

Compressed-air tank, with mounting

Valves, compressed-air

MISCELLANEOUS

General, common info about 591 – 594

Compressed air diagram A20C

Compressed air diagram A20C

STEERING

Comprehensive info, steering

General, common info about 641 – 647

Pressure accumulation, engine dependent pumps 1 and 2

Steering gear

Steering gear, checking and adjusting

Steering gear, changing

Steering arm; steering linkage; track rod

Steering linkage, changing roller bearings in rear lever

Steering linkage, changing roller bearing in front lever

Steering linkage, checking and adjusting

Hydraulic equipment

Damping cylinder, removing and mounting

Damping cylinder, changing seals

Damping cylinder, checking pre-load

Steering cylinder bearing, checking

Steering cylinder, changing spherical bearing

Steering cylinder, reconditioning in machine (left steering cylinder)

Steering valve removed, reconditioning

Steering valve, changing

Steering cylinder, changing

Steering system, checking and adjusting operating pressure

Steering valve neutral position and valve slide axial clearance, checking

Steering damper

FRAME; SPRINGS; DAMPING; AXLE SUSPENSION; WHEEL/TRACK UNIT

FRAME

Frame, complete

Load unit frame, checking dimensions

SUSPENSION

General, common info about 725 – 727

Hollow rubber spring, bump stop

Front rubber springs, changing all

FRAME LINK

Bearings

Frame joint, checking and adjusting clearance

Frame joint, changing metallic bearing

Steering joint and frame joint

Frame link grader

Frame joint, changing hitch

Steering joint, changing spherical bearings

AXLE SUSPENSION

Suspension, front axle

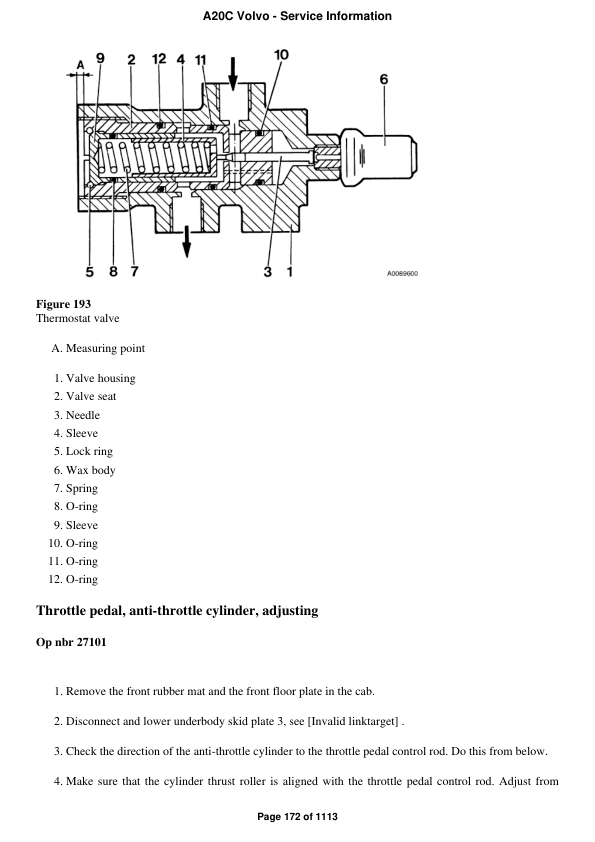

Front A-stay link bearing (rubber bearing), changing

Movable member system, front/rear

Front or rear bogie axle torsion bar, adjusting

Front axle, changing link bearing (rubber bearing)

Bogie suspension

Bogie beam, changing rubber springs

Torsion bar and/or link bearing, changing on load unit

Torsion bar, checking and adjusting

WHEELS; TRACKS; TYRE; HUB; DRUM

Wheel

MACHINERY HOUSE; CAB; EXTERIOR TRIM PARTS ANYWHERE

CAB, NAKED; CANOPY

TRIM PART, OUTSIDE; GLASS; SEALING MOULDING

Glass; sealing moulding

Window pane, changing

CAB INTERIOR/UPHOLSTERY

Driver's seat, complete; instructor's seat

Air spring for operatorŢ€™s seat, changing

OperatorŢ€™s seat, adjusting height of attachment

OperatorŢ€™s seat, mechanical suspension

AIR CONDITIONING UNIT

Air distribution incl. air intake with filter

Heating unit

Heater, changing

Cooling unit

Filling refrigerant R134a

HYDRAULIC SYSTEM; DIGGING/ HANDLING/ GRADING EQUIPM.; MISC. EQUIP.

WORKING HYDRAULICS; SERVO HYDRAULICS

General, common info about 911 – 917

Hydraulic system and component positions

Hydraulic system, bleeding air

Tank; line; oil cooling; filter; breather; filling pump

Working hydraulics

Pump, working hydraulics

Oil pump, changing ground-dependent pump

Oil pump, checking and adjusting hold (standby) pressure

LOAD CARRIER

Hauler/platform body, incl. tipping cylinder; heating; tail gate

Installing piston rod seals

Load body position indicator, adjusting

Load body, adjusting against frame

Load body, changing tipping bearings

Tipping cylinder, changing

Tipping valve, changing

Tipping valve, changing cable

Tipping lever, adjusting

General, common info about 992 – 996

Share