1

/

of

4

Uploader

Volvo EC13 XR Compact Excavator Repair Service Manual Workshop Guide

Volvo EC13 XR Compact Excavator Repair Service Manual Workshop Guide

Regular price

$37.00 USD

Regular price

Sale price

$37.00 USD

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

Manual Included:

Repair Service Manual:

301 Pages

Specifications:

Brand:

Volvo

Model:

A20 6×4 BM

Type:

Articulated Dump Truck

Manuals:

Repair Service Manual

Publication Numbers:

Ref. No 252954 3588

Language:

English

Format:

PDF

Description

Table of Content EC13 XR Service Information

GENERAL

DESCRIPTION, COMPLETE MACHINE

General

Position of components

Warning and information decals

Warning sign – Open engine hood only with engine stopped

Warning sign – Safety distance from the movement area

Warning sign – Safety distance from the work area

SPECIFICATIONS

Fuels, lubricants and filling capacities (litres)

Nominal lifting loads EC13XR

Strength class 8.8 Metric coarse and fine threads

Strength class 10.9 Metric coarse and fine threads

Volvo standard tightening torques

STANDARD PARTS, SERVICE

LUBRICANT; FUEL; OTHER FLUID

SERVICE

General, common info about 171 – 179

Cleanliness, braking and hydraulic system

Repairs in hydraulic system

Maintenance

Creeping of hydraulic cylinders

Deviation when travelling straight ahead

Hydraulic system, replacement of hydraulic filter element1

Maintenance instructions

Measuring the play of the slewing bearing

Track running speed

Emergency measures

Safety equipment, without own function group

Safety is everybody"s concern!

ENGINE WITH MOUNTING AND EQUIPMENT

General, engine installation and its function

Installing the engine

Removing the engine

ENGINE

General, common info about 211 – 218

Engine performance diagram (measuring values for one hour with fan)

Valve mechanism

Checking the compression pressure

LUBRICATING SYSTEM

General, common info about 221 – 224

FUEL SYSTEM

General (common info about 233 – 238)

Fuel pump; filter; strainer

Bleeding the fuel system

Disassembling the fuel pump

Fuel lines

Assembling the fuel injection line

Disassembling the fuel injection line

Control system; control unit (for ex. injection timming adjuster)

Idle speed, inspection and adjustment

INLET SYSTEM; EXHAUST SYSTEM

Inlet manifold; exhaust manifold

COOLING SYSTEM

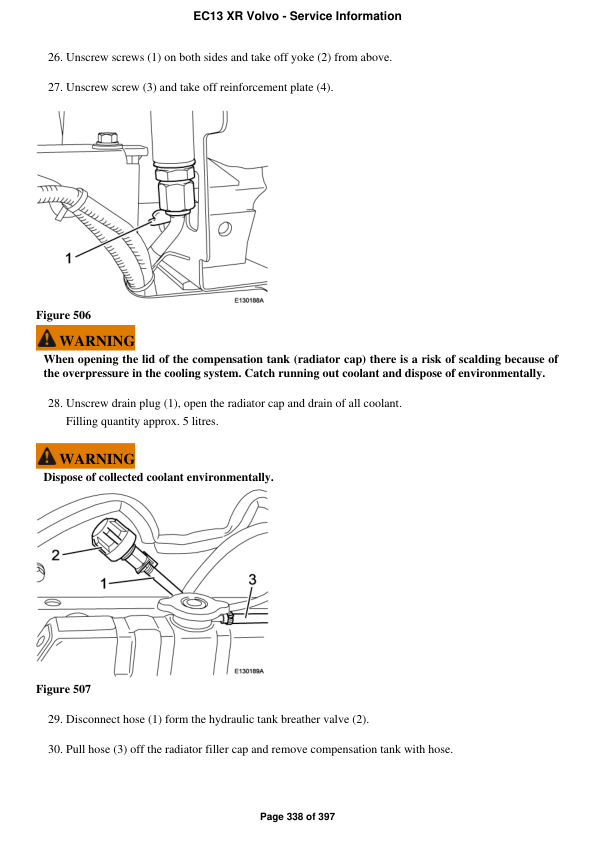

Radiator, mounting and connections included

Removing the radiator

Coolant pump; thermostat

Changing the V-belt

Removing the coolant pump

Removing the thermostat housing

Tensioning the V-belt

ELEC. SYSTEM; WARNING SYSTEM; INFORMATION SYSTEM; INSTRUMENTS

Comprehensive info, electrical system

Designations of electrical components

Electric system, trouble shooting

Electrical system, description

Electrical system, technical data

Identification of plug connectors/lines

Line connections in the wiring loom

Marking of plug connectors

Overview digital immobilizer (option)

Precautions when handling plug connectors

Wiring diagram solenoid valve for ariable track (only XTV design)

Wiring diagram travel system solenoid valveł 2 travel speeds

Wiring diagram, slewing/offsetting

Wiring diagrams

BATTERY; ENERGY STORAGE SYSTEM; MOUNTING PARTS

General, common info about 311 – 313

ALTERNATOR; CHARGING; ELECTRIC MOTOR; ELECTRIC DRIVES

General, common info about 321 – 322

Battery, generator, dashboard

Tests before disassembly

Wiring diagram, electric power supply

Alternator inclusive drive

Removing the generator

Charging; converter

Checking the performance characteristics

Checking the voltage regulation

STARTING SYSTEM

General, common info about 331 – 334

Starter, preheating relay, ignition switch

Wiring diagram, starter system

Starter motor inclusive solenoid

Assembling the starter

Dismantling the starter

Installation of the solenoid

Key-operated engine shut down system with EDD-solenoid

Electric air pre-heater, excluding element

Characteristics of the glow plug system

Installing the glow plug

LIGHTING

General, common info about 351 – 356

Boom/roll over protection system

Wiring diagram for lighting

Lighting, extra, including working lighting

Working headlights and main headlights, specification

Working headlights and main headlights, description

OTHER ELECTRICAL EQUIPMENT

General, common info about 361 – 367

Operating/control elements on driverŢ€™s platform

Wiring diagram, socket (12 V)

Audible warning from horn; mounting

Wiring diagram, external warning system

CABLE; FUSE; RELAY

Cable; battery disconnector

Main wiring loom/main plug connector roll over protection structure

Electrical distribution box; fuse box; junction box

Fuses for machine equipment

INSTRUMENT; SENSOR; WARNING AND INFORMATION SYSTEM

General, common info about 383 – 387

Electrical components (hydraulic system side)

Sender, monitoring system

Electrical components (machine side)

Wiring diagram for sensor, control/warning system

Warning/information unit, display unit

Wiring diagram for dashboard

POWER TRANSMISSION

General, common info about 410 – 436

General notes to be observe when working on power transmission assemblies

HYDROSTATIC DRIVE

General, common info about 441 – 443

Technical data

Hydraulic motor incl. operating system.

Travel motor

Disassembling the travel motor

Dismantling the travel gear

Hydraulic motor ހ" slewing of superstructure

Installing the travel motor

Centre passage; lines

BRAKE

TRACK BRAKE

STEERING

Comprehensive info, steering

Steering system, description

FRAME; SPRINGS; DAMPING; AXLE SUSPENSION; WHEEL/TRACK UNIT

FRAME

General, common info about 711 – 718

Frame, technical data

Frame, excavator

Assembling the cylinder for adjustable track width

Assembling the superstructure

Removing the cylinder for adjustable track width

Removing the superstructure

WHEELS; TRACKS; TYRE; HUB; DRUM

General, common info about 771 – 775

Drive gear, tightening torque

Track supporting idler, tightening torque

Crawler unit

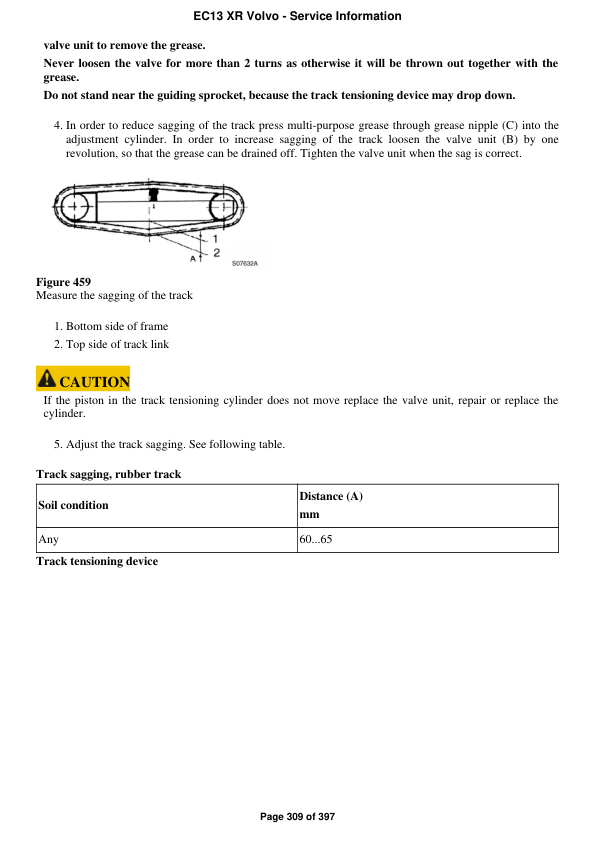

Adjusting the track sagging

Assembling the rubber track

Drive sprocket

Removing the rubber track

Removing the sliding bar

Removing the guide sprocket

MACHINERY HOUSE; CAB; EXTERIOR TRIM PARTS ANYWHERE

Comprehensive info, machinery house and cab

Roll over protection structure

Roll over protection structure, specification

HYDRAULIC SYSTEM; DIGGING/ HANDLING/ GRADING EQUIPM.; MISC. EQUIP.

Hydraulic system, description

WORKING HYDRAULICS; SERVO HYDRAULICS

General, common info about 911 – 917

Adjusting the pressure and checking for leaks

General notes to be observe when working on the hydraulic system

Tank; line; oil cooling; filter; breather; filling pump

Changing the hydraulic oil

Changing the hydraulic oil filter

Checking the hydraulic oil level

Hydraulic oil tank, filling capacity

Removing the oil cooler

Working hydraulics

Adjustment of secondary valves Test and adjustment procedure

Checking and adjusting the breaker (volumetric capacity)

Checking and adjusting the pressure relief valve

Control valve block for slewing gear Test and adjustment

Dismantling the valve block

Hose rupture valve on boom cylinder

Hose rupture valve on boom cylinder Testł andł adjustment procedure

Pressure relief valves

Removing the valve block

Solenoid valve for hydraulic working unit

Test and adjustment values for EC13XR/XTV

Tests and adjustments of the power control

Valve block for slewing gear

Way valve, control valve

Pump, working hydraulics

Removing the hydraulic oil pump

MISCELLANEOUS

General, common info about 992 – 996

Hydraulic circuit for dozer blade and adjustable track width

Return flow, hydraulic circuit for accessories

Share